Copper Tubes

TALOSⓇ ACR INNER GROOVED

Heat Exchangers

TALOSⓇ IGT copper tubes feature inner grooves that enhance the heat transferred by the refrigerant and as a result increase the energy efficiency of the HVACR units. Applications of TALOSⓇ IGT include heat exchangers for condensation and/or evaporation in A/C and refrigeration systems, as well as, heat pumps.

HALCOR’s production technology for TALOSⓇ IGT copper tubes enables the manufacture of advanced inner-groove designs for a complete range of sizes, starting from 16mm outside diameter down to the new generation microgrooveTM tubes with an outside diameter of 5mm or less, being one of the few manufacturers worldwide to have this capability.

The ability of Halcor to provide complete solutions to its clients was reinforced by the establishment of a Tube Heat Transfer Laboratory. The equipment of the Tube Heat Transfer Laboratory was specially designed to enable measurements of the heat transfer performance of ACR tubes under fully controlled test conditions. Critical features, such as, the heat transfer co-efficient and the pressure drop, are measured using a sophisticated system for condensation and evaporation of HFC and natural refrigerants, as well as, single-phase fluids and fluid mixtures. The flow and thermal parameters are programmed to simulate specific operating conditions, such as, refrigerant flow rate, saturation temperature, vapor quality, thermal capacity, etc. and thus allow Halcor’s engineers to study the influence of the inner-groove design.

The Tube Heat Transfer Laboratory gives Halcor the capability to incorporate the test results in a complete framework of technical support to manufacturers of heat-exchangers, with the purpose of optimizing their heat-exchanger design for any of the following:

- Improved efficiency

- Higher capacity

- Reduction of raw material

- Compact heat-exchanger size

- Reduction of refrigerant charge

The Tube Heat Transfer Laboratory offers a superior advantage to Halcor’s clients by giving them the opportunity to establish a mutually beneficial co-operation within an integrated support and product development framework.

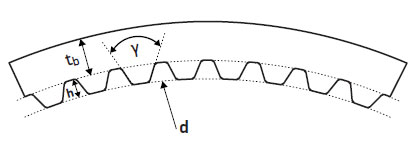

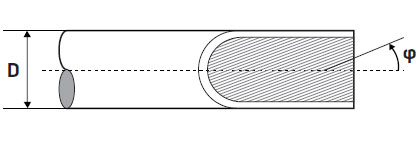

D : Outside Diameter

d: Inside Diameter

tb: Bottom Wall Thickness

h: Groove Depth

φ: Lead Angle

γ: Top Angle

| External diameter D (mm) | Bottom wall thickness tb (mm) | Groove depth h (mm) | Top angle γ (deg) | Lead angle φ (deg) | Number of grooves n | Unit weight(g/m) |

|---|---|---|---|---|---|---|

| 5,00 | 0,20-0,23 | 0,12-0,15 | 11-40 | 18-40 | 40-58 | 32-35 |

| 6,35 | 0,23-0,27 | 0,15-0,16 | 12-40 | 18-28 | 45-54 | 46-53 |

| 7,00 | 0,21-0,27 | 0,10-0,24 | 10-53 | 15-40 | 50-70 | 46-60 |

| 7,94 – 8,00 | 0,23-0,41 | 0,12-0,22 | 12-42 | 18-43 | 50-80 | 57-69 |

| 9,52 | 0,27-0,45 | 0,15-0,25 | 20-90 | 15-30 | 55-85 | 80-128 |

| 11,90-12,00 | 0,32-0,40 | 0,17-0,25 | 15-55 | 16-30 | 70-98 | 120-145 |

| 12,70 | 0,32-0,41 | 0,23-0,25 | 30-58 | 18-30 | 70-75 | 135-170 |

| 15,00 – 15,90 | 0,35-0,50 | 0,25-0,35 | 30-53 | 18-30 | 30-75 | 188-259 |