Brochures

Learn more about the product

Engineered for reliability and performance, each product offers exceptional value, ensuring long-lasting solutions that enhance your experience.

The rising demand of the international community for a green and safe environment has put pressure on the use of HFC refrigerants for HVAC&R applications. At the same time, the use of Carbon Dioxide (CO2) as a refrigerant thrives and installations of CO2 (R-744) refrigeration systems are increasing at a high rate around the world.

CO2 is a natural refrigerant with zero ODP and a GWP of 1, being one of the best choices from an environmental perspective. CO2 refrigeration cycles, require high operating pressures in order to operate efficiently. Several technologies that improve the efficiency of CO2 systems have been established and are under development and optimization (e.g. ejectors, parallel compression, adiabatic cooling, etc.). New technologies lead to new and specialized design conditions that result in different levels of operating and design pressure and temperature.

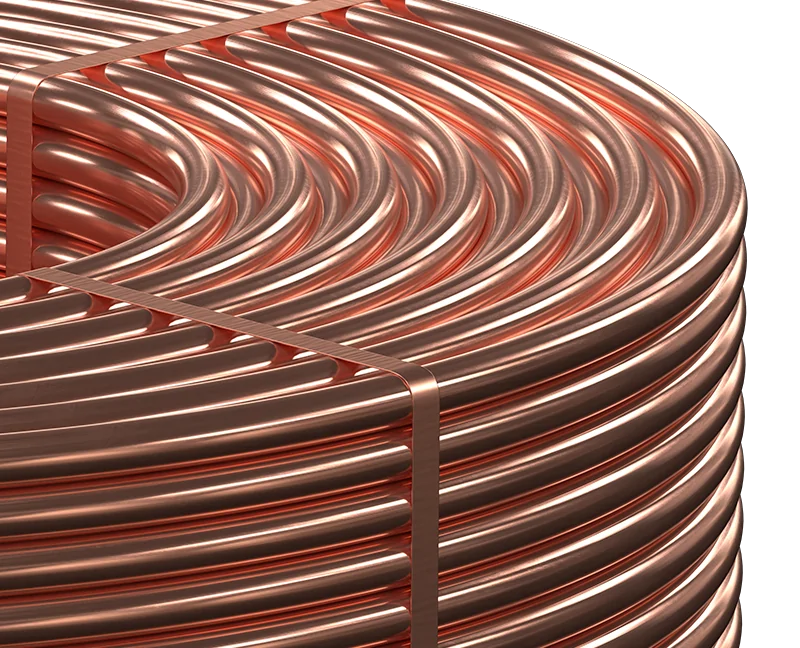

TALOS®S60 tubes are specifically designed for a maximum allowable pressure of 60bar and feature a reinforced wall thickness in comparison with the standardized TALOS®ACR tube range.

Combined with TALOS®XS for 120/130bar and TALOS®S80 for 80bar, TALOS®S60 for 60bar completes Halcor’s copper tube portfolio for CO2applications and provides the HVAC&R designer a full range of choices corresponding to the unique design conditions.

The well-known installation practices of refrigeration copper tubes apply both in systems and in the field (see relevant EN378 standard for guidelines).

Copper phosphorus deoxidised (Cu-DHP), having minimum copper content 99,90% and P = 0,015% – 0,040%.

| TALOS®S60 for 60bar1 | |||

|---|---|---|---|

| Outer Diameter | Wall Thickness | ||

| [inch] | [mm] | [mm] | [inch] |

| 5/16” | 7,94 | 0,70 | 0,028 |

| 3/8” | 9,53 | 0,70 | 0,028 |

| 1/2” | 12,7 | 0,70 | 0,028 |

| 5/8” | 15,88 | 0,80 | 0,031 |

| 3/4” | 19,05 | 0,91 | 0,036 |

| 7/8” | 22,23 | 1,10 | 0,043 |

| 1 1/8” | 28,58 | 1,42 | 0,056 |

| 1 3/8” | 34,93 | 1,73 | 0,068 |

| 1 5/8” | 41,28 | 2,05 | 0,081 |

| 2 1/8” | 53,98 | 2,67 | 0,105 |

| 2 5/8” | 66,68 | 3,30 | 0,130 |

¹Maximum Allowable Pressure calculation acc. to EN 14276:2020. For service temperatures from -196°C up to 100°C.

Learn more about the product

Our product range is designed with a commitment to excellence, delivering unmatched durability and efficiency to meet your needs. Engineered for reliability and performance, each product offers exceptional value, ensuring long-lasting solutions that enhance your experience.

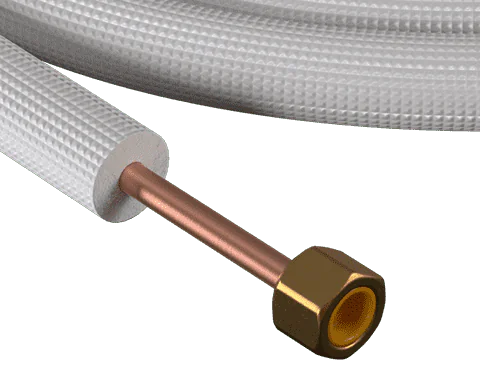

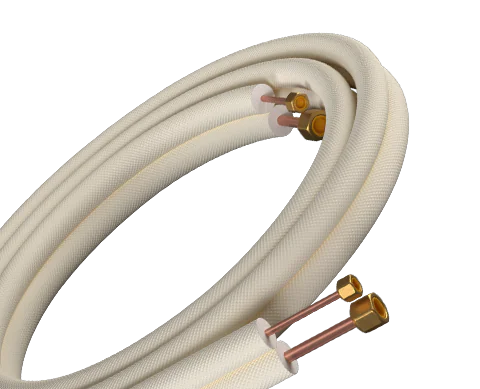

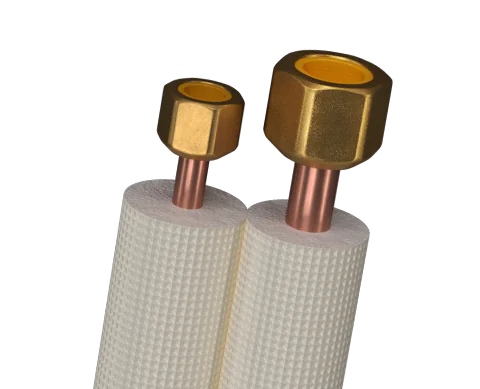

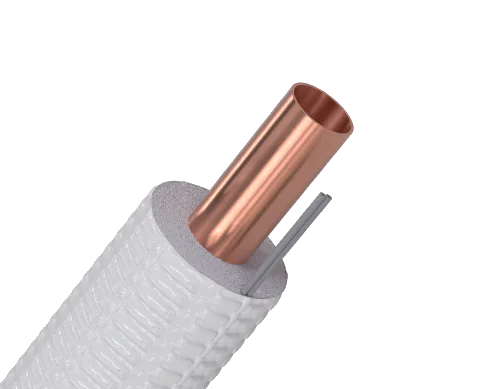

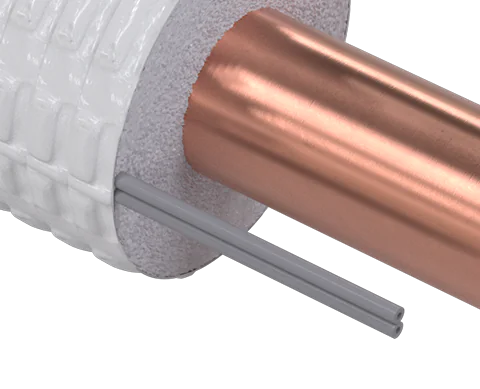

TALOS® ACR Linesets are designed especially for the split Air-Conditioning and Heat Pump Systems products requiring installation with flared connections. The unique advantages offered by TALOS® ACR Linesets, including, copper resistance and durability, high performance foam insulation and pre-flared ends with mounted flare nuts, result in significant energy savings and in quick, cost effective field installations.

Copper phosphorus deoxidised (DHP-Cu) with min. copper content 99,90% and P=0,015% – 0,040%.

REFRIGERATION PIPES: EN 12735-1

FOAM INSULATION: EN 13501-1

FLARE FITTINGS: SAE J513.

REFRIGERATION PIPES: AENOR, TÜV, GL.

Follow the equipment manufacturer’s installation instructions regarding refrigerant tubing, system evacuation and testing for leaks.

| Temper | EN 12735 Classification | Minimum Tensile strength Rm (MPa) | Min elongation, A% |

|---|---|---|---|

| Soft | R-220 | 220 | 40 |

| COPPER TUBE EXTERNAL DIAMETER INCH | COPPER TUBE EXTERNAL DIAMETER MM | COPPER TUBE WALL THICKNESS MM | OVERALL EXTERNAL DIAMETER WITH 9MM THICK INSULATION MM |

|---|---|---|---|

| 3/16 | 4,76 | 0,80 | 22,76 |

| 1/4 | 6,35 | 0,80 | 24,35 |

| 5/16 | 7,94 | 0,80 | 25,94 |

| 3/8 | 9,52 | 0,80 | 25,72 |

| 1/2 | 12,70 | 0,80 | 30,70 |

| 5/8 | 15,87 | 1,00 | 33,87 |

| 3/4 | 19,05 | 1,00 | 37,05 |

| 7/8 | 22,23 | 1,00 | 40,23 |

Values are listed, as obtained under standard laboratory conditions and may be amended, without prior notice.

| COPPER TUBE EXTERNAL DIAMETER INCH | COPPER TUBE EXTERNAL DIAMETER MM | COPPER TUBE WALL THICKNESS MM | OVERALL EXTERNAL DIAMETER WITH 9MM THICK INSULATION MM |

|---|---|---|---|

| ¼-3 / 8 | 6,35-9,52 | 0,80-0,80 | 24,4-27,5 |

| ¼-1 / 2 | 6,35-12,7 | 0,80-0,80 | 24,4-30,7 |

| ¼-5 / 8 | 6,35-15,88 | 0,80-1,00 | 24,4-33,9 |

| ¼-3 / 4 | 6,35-19,05 | 0,80-1,00 | 24,4-37,10 |

| 3 / 8-1 / 2 | 9,52-12,7 | 0,80-0,80 | 27,5-30,7 |

| 3 / 8-5 / 8 | 9,52-15,88 | 0,80-1,00 | 27,5-33,9 |

| 3 / 8-3 / 4 | 9,52-19,05 | 0,80-1,00 | 27,5-37,1 |

| ½-3 / 4 | 12,7-19,05 | 0,80-1,00 | 30,7-37,1 |

Other sizes and special packaging in pallets or cardboard boxes are available upon request.

Other sizes and special packaging in pallets or cardboard boxes are available upon request.

| MATERIAL | PE-X foam |

| DENSITY ACCORDING TO DIN 53420 ASTM D 1667 | 30-33 Kg/m3 |

| THERMAL CONDUCTIVITY COEFFICIENT (λ) ACCORDING TO ASTM C 335 | 0,039 W/m.K |

| VAPOUR-WATER DIFFUSSION RESISTANCE COEFFICIENT (μ) ACCORDING TO ISO 12572 | > 9.000 |

| WORKING TEMPERATURE | -80oC to +110oC |

| FIRE RESISTANCE | EN 13501–1, Class B or Class E, DIN 4102, B2, BS 476, NF P 92 501-M1 |

| RESISTANCE TO CHEMICAL AGENTS ACC. TO ASTM 543-56 T | Very good |

| SOUND ABSORPTION ACC. TO DIN 4109 300-2500Hz | ~60% |

| DIMENSIONAL STABILITY ACCORDING TO ISO 2796 FOR TEMPERATURES UP TO 1000C | <5% |

Values are listed, as obtained under standard laboratory conditions and may be amended, without prior notice.

Our product range is designed with a commitment to excellence, delivering unmatched durability and efficiency to meet your needs.

In the sensitive healthcare areas and installations, it is imperative to use materials that safeguard cleanliness and have a neat appearance and durability. TALOS® MEDTM copper tubes, can withstand high operating pressures with unlimited durability, thanks to the natural strength of copper, hence they are the ideal choice for the construction of medical gases distribution networks. TALOS® MEDTM copper tubes are manufactured according to the requirements of standard EN 13348. They are supplied with end caps to prevent contamination from dust and other particles during storage or transportation.

Copper phosphorus deoxidised (DHP-Cu) with minimum copper content 99,90% and Ρ= 0,015% – 0,040%.

EN 13348

BSI

| Temper | EN 13348 Classification | Minimum Tensile strength Rm (MPa) | Min elongation, A% |

|---|---|---|---|

| Soft | R-220 | 220 | 40 |

| Half hard | R-250 | 250 | 30 |

| Hard | R-290 | 290 | 3 |

| Diameter x Thickness Dxs (mm) | Internal diameter (mm) | Nominal copper weight (kg/m) | External surface area (m²/m) | Full volume (l/m) | Packing (m) |

|---|---|---|---|---|---|

| 6×1,00 | 4,0 | 0,140 | 0,019 | 0,013 | Straight lengths of 5m |

| 8×1,00 | 6,0 | 0,196 | 0,025 | 0,028 | Straight lengths of 5m |

| 10×1,00 | 8,0 | 0,252 | 0,031 | 0,050 | Straight lengths of 5m |

| 12×1,00 | 10,0 | 0,308 | 0,038 | 0,079 | Straight lengths of 5m |

| 15×1,00 | 13,0 | 0,391 | 0,047 | 0,133 | Straight lengths of 5m |

| 18×1,00 | 16,0 | 0,475 | 0,957 | 0,201 | Straight lengths of 5m |

| 22×1,00 | 20,0 | 0,587 | 0,069 | 0,314 | Straight lengths of 5m |

| 22×1,20 | 19,6 | 0,698 | 0,069 | 0,302 | Straight lengths of 5m |

| 28×1,00 | 26,0 | 0,755 | 0,088 | 0,531 | Straight lengths of 5m |

| 28×1,50 | 25,0 | 1,111 | 0,088 | 0,491 | Straight lengths of 5m |

| 35×1,50 | 32,0 | 1,405 | 0,110 | 0,804 | Straight lengths of 5m |

| 42×1,50 | 39,0 | 1,700 | 0,132 | 1,195 | Straight lengths of 5m |

| 54×2,00 | 50,0 | 2,908 | 0,170 | 1,963 | Straight lengths of 5m |

| 64×2,00 | 60,0 | 3,467 | 0,201 | 2,827 | Straight lengths of 5m |

| 66,7Χ2,00 | 62,7 | 3,618 | 0,210 | 3,088 | Straight lengths of 5m |

| 76,1×2,00 | 72,1 | 4,144 | 0,239 | 4,083 | Straight lengths of 5m |

| 88,9×2,00 | 84,9 | 4,857 | 0,279 | 5,661 | Straight lengths of 5m |

| 108×2,50 | 103,0 | 7,375 | 0,339 | 8,332 | Straight lengths of 5m |

Learn more about the product

Our product range is designed with a commitment to excellence, delivering unmatched durability and efficiency to meet your needs.

TALOS SOLAR PLUS™ tubes are specially engineered for solar panel applications. The extra clean outer surface of TALOS SOLAR PLUS™ tubes enables the optimization of the welding process between copper or aluminium absorber sheets when using ultrasonic or laser joining technologies. Increased welding speeds and minimization of pre-cleaning operation lead to savings of time and money in the manufacturing of solar absorber panels. The high thermal conductivity of copper ensures an improved thermal efficiency of the solar absorber panel.

Hard (R360 and R290) and Soft (R220) in level wound coils (LWC).

Hard (R360 and R290), Half-Hard (R250) and Soft (R220) in straight lengths.

Copper phosphorus deoxidized (DHP-Cu) with min. copper content 99,90% and P=0,015%-0,040%.

According to EN 12449 or ASTM B75.

| OUTSIDE DIAMETER (MM) | WALL THICKNESS (MM) |

|---|---|

| 6 | 0,30 – 1,20 mm |

| 8 | 0,30 – 1,20 mm |

| 9 | 0,30 – 1,20 mm |

| 10 | 0,30 – 1,20 mm |

| 11 | 0,30 – 1,20 mm |

| 12 | 0,30 – 1,20 mm |

| 18 | 0,30 – 1,20 mm |

| 22 | 0,30 – 1,20 mm |

| LWC COIL WEIGHT (KG) | STRAIGHT LENGTHS (M) |

|---|---|

| 75 | 0,30 – 6,00 m |

| 85 | 0,30 – 6,00 m |

| 115 | 0,30 – 6,00 m |

| 150 | 0,30 – 6,00 m |

| 200 | 0,30 – 6,00 m |

| 290 | 0,30 – 6,00 m |

| 460 | 0,30 – 6,00 m |

| 580 | 0,30 – 6,00 m |

| Outer diameter | Max. 1350 mm |

| Inner diameter | 610 mm |

| Height | 150-600 mm |

| Coils | On wooden pallet, with cardboard inserts and corrosion inhibitor (VCI) protective film |

| Straight lengths | Bundles wrapped in corrosion inhibitor (VCI) protective film in wooden pallets |

| OUTSIDE DIAMETER OF COPPER TUBE MM | WALL THICKNESS MM | TOTAL DIAMETER WITH 13MM THICK INSULATION MM | BEND RADIUS |

|---|---|---|---|

| 10 | 1,0 | 36 | |

| 11 | 1,0 | 37 | |

| 12 | 1,0 | 38 | 4XOD |

| 15 | 1,0 | 41 | 4XOD |

| 18 | 1,0 | 44 | 4XOD |

| 22 | 1,0 | 48 | 4XOD |

Learn more about the product

Our product range is designed with a commitment to excellence, delivering unmatched durability and efficiency to meet your needs.

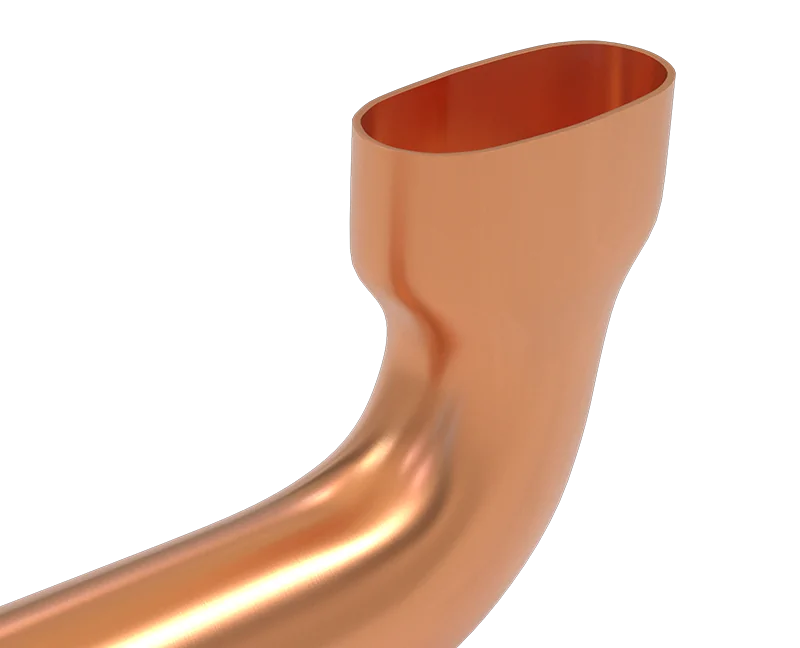

TALOS® FORM is an advanced copper tube with exceptional forming capability. TALOS®FORM is characterized by the ability to be formed into shapes that require a high degree of elongation. This advanced forming ability finds application in the manufacturing of critical HVACR elements, such as connection fittings for boilers, heat exchangers parts and other intricate-formed components.

The use of TALOS® FORM over standard tubing ensures higher productivity, by requiring a smaller number of forming steps to achieve a precise shape. At the same time, components made from TALOS® FORM achieve excellent functional quality.

The enhanced properties of TALOS® FORM are achieved through a highly controlled production process, specifically designed for the particular purpose. The high level of formability of TALOS® FORM is verified through measurement of the tube expansion behavior, following the standardized test method EN ISO 8493.

Copper phosphorus deoxidised (Cu-DHP), having minimum copper content 99,90% and P = 0,015% – 0,040%.

EN 12735-2, EN12449, Internal Company Specification

Light Annealed in spools (LWC) with or without central carton support.

Availability

| LWG coil weight (kg) | 115, 150, 200, 460 |

| Outside diameter (mm) | 4-22 |

| Wall thicknessς (mm) | 0,50 – 1,20 |

| Outer diameter (mm) | max. 1350 |

| Inner diameter (mm) | 610 |

| Height (mm) | 150 – 600 |

Learn more about the product

Our ECUTHERM SOLAR product combines durability with energy efficiency, utilizing a inner insulation layer of PES for high temperature resistance and an external layer of advanced PEX (cross-linked polyethylene) technology to deliver long-lasting performance and significant energy savings.

TALOS® ECUTHERM SOLAR copper tubes are manufactured according to European and U.S. Specifications.

TALOS® ECUTHERM™ SOLAR copper tubes are coated with a 3-layer system. To begin with, a high-temperature resistant PES insulation layer is positioned on the outside of the copper tube. furthermore, an industrial insulation of cross-linked polyethylene (PE-X) foam structured in closed micro-cells provides thermal insulation. On top of that , an external covering creates an integral resistance barrier against the external environment.

Phosphorus deoxidized copper (Cu-DHP) in soft temper (R220), according to EN and ASTM standards.

| MATERIAL | PE-X or PE foam |

| DENSITY ACCORDING TO DIN 53420 ASTM D 1667 | 30-33 Kg/m3 |

| THERMAL CONDUCTIVITY COEFFICIENT (λ) ACCORDING TO EN ISO 8497 | 0,0357 W/mK (0oC)0,0389 W/mK (40oC)​ |

| VAPOUR-WATER DIFFUSSION RESISTANCE COEFFICIENT (μ) ACCORDING TO EN 13469 | 12.500 |

| WORKING TEMPERATURE | -80oC to +150oC |

| FIRE RESISTANCE | ΕΝ 13501 |

| RESISTANCE TO CHEMICAL AGENTS ACC. TO ASTM 543-56 T | Very good |

| DIMENSIONAL STABILITY ACCORDING TO ISO 2796 FOR TEMPERATURES UP TO 1000C | <5% |

| INSULATION FILM WITH UV PROTECTION | 300μm |

Values are listed, as obtained under standard laboratory conditions and may be amended, without prior notice.

(Roll Lengths 10, 15, 20, 25 meters) Talos ECUTHERM™ Solar

| OUTSIDE DIAMETER OF COPPER TUBE MM | WALL THICKNESS MM | TOTAL DIAMETER WITH 13MM THICK INSULATION | BEND RADIUS |

|---|---|---|---|

| 10 | 0,50 | 36 | |

| 11 | 0,60 | 37 | |

| 12 | 0,60 | 38 | 4xOD |

| 15 | 0,70 | 41 | 4xOD |

| 18 | 0,75 | 44 | 4xOD |

| 22 | 0,90 | 48 | 4xOD |

12/12, 15/15, 18/18, 22/22

| CONDUCTOR MATERIAL | FLEXIBILITY OF CONDUCTOR | COLOR | NO. OF POLES | NOMINAL VOLTAGE VO/V | NOMINAL CROSS SECTION OF CONDUCTOR |

|---|---|---|---|---|---|

| COPPER | Flexible, CLASS E | White | 2 | 300/300 | 2 X 0,75 mm2 |

Values are listed, as obtained under standard laboratory conditions and may be amended, without prior notice.

Learn more about the product