Brochures

Learn more about our product:

Our product range is designed with a commitment to excellence, delivering unmatched durability and efficiency to meet your needs. Engineered for reliability and performance, each product offers exceptional value, ensuring long-lasting solutions that enhance your experience.

Copper is an ideal material for tubes used in water installations due to its inherent properties. TALOS® copper tubes for the sanitary and heating applications provide substantial advantages, such as, stable physical and mechanical properties, resistance to high operating pressures and temperatures, air -and water- tightness, antimicrobial properties, ease of installation and long-term cost-effectiveness, standardization in accordance with international regulations.

TALOS® copper tubes ensure the safe and secure operation of plumbing systems for decades and its resistance to corrosion is guaranteed by the cleaning method utilized during manufacturing.

The effectiveness of the TALOS® cleaning process has been tested and certified by well-recognized quality organizations.

TALOS® copper tubes, manufactured according to the specifications of European Norm EN1057, are CE marked in accordance with regulation (EU) No.305/2011 for Construction Products.

Copper phosphorus deoxidised (DHP-Cu) with min. copper content 99,90% and Ρ=0,015% – 0,040%.

BSI, AFNOR, NSAI, AENOR, RAL / DVGW, KIWA / GASTEC-QA, SITAC, STF VTT, GOST, VIK.

| Temper | EN 1057 Classification | Minimum Tensile strength Rm (MPa) | Min elongation, A% |

|---|---|---|---|

| Soft | R-220 | 220 | 40 |

| Half Hard | R-250 | 250 | 20 or 30* |

| Hard | R-290 | 290 | 3 |

*depending on the dimension

STRAIGHT HALF HARD

| Diameter x Thickness Dxs (mm) | Internal diameter (mm) | Nominal copper weight (kg/m) | External surface area (m2/m) | Filling volume (l/m) |

|---|---|---|---|---|

| 10X0,70 | 8,6 | 0,182 | 0,031 | 0,058 |

| 10Χ1,00 | 8,0 | 0,252 | 0,031 | 0,050 |

| 12Χ0,70 | 10,6 | 0,221 | 0,038 | 0,088 |

| 12Χ1,00 | 10,0 | 0,308 | 0,038 | 0,079 |

| 15Χ0,70 | 13,6 | 0,280 | 0,047 | 0,145 |

| 15Χ0,80 | 13,4 | 0,318 | 0,047 | 0,141 |

| 15Χ1,00 | 13,0 | 0,391 | 0,047 | 0,133 |

| 18Χ0,80 | 16,4 | 0,384 | 0,057 | 0,211 |

| 18Χ1,00 | 16,0 | 0,475 | 0,057 | 0,201 |

| 22Χ0,80 | 20,4 | 0,474 | 0,069 | 0,327 |

| 22Χ1,00 | 20,0 | 0,587 | 0,069 | 0,314 |

| 22Χ1,50 | 19,0 | 0,860 | 0,069 | 0,284 |

| 28Χ0,90 | 26,2 | 0,682 | 0,088 | 0,539 |

| 28Χ1,00 | 26,0 | 0,755 | 0,088 | 0,531 |

| 28Χ1,50 | 25,0 | 1,111 | 0,088 | 0,491 |

| 35Χ1,20 | 32,6 | 1,134 | 0,110 | 0,835 |

| 35Χ1,50 | 32,0 | 1,405 | 0,110 | 0,804 |

| 42Χ1,20 | 39,6 | 1,369 | 0,132 | 1,232 |

| 42Χ1,50 | 39,0 | 1,699 | 0,132 | 1,195 |

| 54Χ1,20 | 51,6 | 1,772 | 0,170 | 2,091 |

| 54Χ2,00 | 50,0 | 2,908 | 0,170 | 1,963 |

| 66,7Χ1,20 | 64,3 | 2,198 | 0,210 | 3,247 |

| 66,7Χ2,00 | 62,7 | 3,618 | 0,210 | 3,088 |

| 76,1Χ1,50 | 73,1 | 3,129 | 0,236 | 4,197 |

| 76,1Χ2,00 | 72,1 | 4,44 | 0,239 | 4,083 |

STRAIGHT HARD

| Diameter x Thickness Dxs (mm) | Internal diameter (mm) | Nominal copper weight (kg/m) | External surface area (m2/m) | Filling volume (l/m) |

|---|---|---|---|---|

| 10X0,80 | 8,4 | 0,206 | 0,031 | 0,055 |

| 10X1,00 | 8,0 | 0,252, | 0,031 | 0,050 |

| 12X0,80 | 10,4 | 0,251 | 0,038 | 0,085 |

| 12Χ1,00 | 10,0 | 0,308 | 0,038 | 0,079 |

| 14X0,80 | 12,4 | 0,295 | 0,044 | 0,121 |

| 14X1,00 | 12,0 | 0,363 | 0,044 | 0,133 |

| 15X0,80 | 13,4 | 0,318 | 0,047 | 0,141 |

| 15X1,00 | 13,00 | 0,391 | 0,047 | 0,133 |

| 16X1,00 | 14,00 | 0,419 | 0,050 | 0,154 |

| 18X0,80 | 16,4 | 0,385 | 0,057 | 0,211 |

| 18X1,00 | 16,0 | 0,475 | 0,057 | 0,201 |

| 22X0,90 | 20,2 | 0,531 | 0,069 | 0,320 |

| 22X1,00 | 20,0 | 0,587 | 0,069 | 0,314 |

| 28X0,90 | 26,2 | 0,682 | 0,088 | 0,539 |

| 28X1,00 | 26,0 | 0,755 | 0,088 | 0,531 |

| 28X1,50 | 25,0 | 1,111 | 0,088 | 0,491 |

| 35X1,00 | 33,0 | 0,950 | 0,110 | 0,855 |

| 35X1,50 | 32,0 | 1,405 | 0,110 | 0,804 |

| 35X2,00 | 31,0 | 1,844 | 0,110 | 0,755 |

| 42X1,00 | 40,0 | 1,1,46 | 0,132 | 1,257 |

| 42X1,20 | 39,6 | 1,368 | 0,132 | 1,232 |

| 42X1,50 | 39,0 | 1,700 | 0,132 | 1,195 |

| 54X1,00 | 52,0 | 1,484 | 0,170 | 2,124 |

| 54X1,20 | 51,6 | 1,771 | 0,170 | 2,091 |

| 54X1,50 | 51,0 | 2,202 | 0,170 | 2,043 |

| 54X2,00 | 50,0 | 2,908 | 0,170 | 1,963 |

| 64X2,00 | 60,0 | 3,467 | 0,201 | 2,827 |

| 66,7X1,20 | 64,3 | 2,198 | 0,210 | 3,247 |

| 66,7X2,00 | 62,7 | 3,618 | 0,210 | 3,088 |

| 76,1X1,50 | 73,1 | 3,129 | 0,239 | 4,197 |

| 76,1X2,00 | 72,1 | 4,144 | 0,239 | 4,083 |

| 88,9X2,00 | 84,9 | 4,859 | 0,279 | 5,661 |

| 108X2,00 | 104,0 | 5,928 | 0,339 | 8,495 |

| 108X2,50 | 103,0 | 7,375 | 0,339 | 8,332 |

SOFT COILS

| Diameter x Thickness Dxs (mm) | Internal diameter (mm) | Nominal copper weight (kg/m) | External surface area (m2/m) | Filling volume (l/m) |

|---|---|---|---|---|

| 6Χ1,00 | 4,0 | 0,140 | 0,019 | 0,013 |

| 8Χ0,60 | 6,8 | 0,124 | 0,025 | 0,036 |

| 8X1,00 | 6,0 | 0,196 | 0,025 | 0,028 |

| 10X0,70 | 8,6 | 0,182 | 0,031 | 0,058 |

| 10X1,00 | 8,0 | 0,252 | 0,031 | 0,050 |

| 12X1,00 | 10,0 | 0,308 | 0,038 | 0,079 |

| 14X1,00 | 12,0 | 0,363 | 0,044 | 0,113 |

| 15X1,00 | 13,0 | 0,391 | 0,047 | 0,133 |

| 15X1,50 | 12,0 | 0,566 | 0,047 | 0,113 |

| 16X1,00 | 14,0 | 0,419 | 0,050 | 0,154 |

| 18X1,00 | 16,0 | 0,475 | 0,057 | 0,201 |

| 22X1,00 | 20,0 | 0,587 | 0,069 | 0,314 |

| 22X1,50 | 19,0 | 0,860 | 0,069 | 0,284 |

| 28X1,50 | 25,0 | 1,111 | 0,088 | 0,491 |

Non standard dimensions are manufactured upon request.

Learn more about our product:

Discover our quality marks:

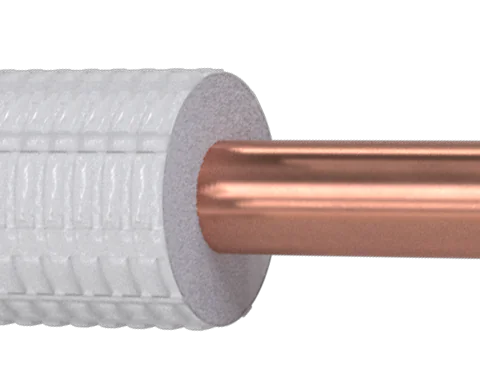

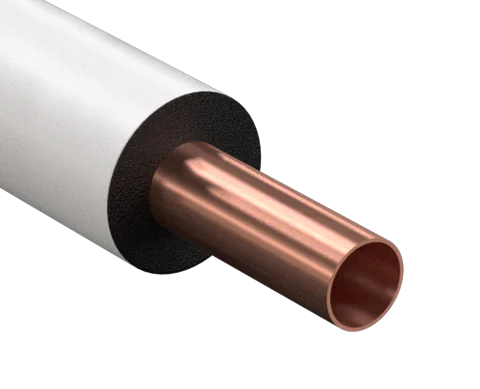

Our ECUTHERM product range combines durability with energy efficiency, utilizing advanced PEX (cross-linked polyethylene) technology to deliver long-lasting performance and significant energy savings.

Copper phosphorus deoxidised (DHP-Cu) with min. copper content 99,90% and Ρ=0,015% – 0,040%.

ΤALOS ECUTHERM™ : WATER PIPES: EN 1057

TALOS ACR ECUTHERM™ : REFRIGERATION PIPES EN 12735-1

WATER PIPES: RAL / DVGW, BSI, AFNOR, AENOR, CSTB (Avis Technique), NSAI, KIWA / GASTEC-QA, SITAC, STF VTT, GOST VIK.

REFRIGERATION PIPES: TÜV, GL.

Read our brochure for detailed product specifications:

| Temper | EN 1057/12735-1 Classification | Minimum Tensile strength Rm (MPa) | Min elongation, A% |

|---|---|---|---|

| Soft | R-220 | 220 | 40 |

| MATERIAL | PE-X or PE foam |

| DENSITY ACCORDING TO DIN 53420 ASTM D 1667 | 30-33 Kg/m3 |

| THERMAL CONDUCTIVITY COEFFICIENT (λ) ACCORDING TO EN ISO 8497 | 0.0357 W/mK (0oC)0,0389 W/mK (40oC) |

| VAPOUR-WATER DIFFUSSION RESISTANCE COEFFICIENT (μ) ACCORDING TO EN 13469 | 12.500 |

| WORKING TEMPERATURE | -80oC to +110oC(+90oC for PE foam) |

| FIRE RESISTANCE | EN 13501–1, Class B or Class E, DIN 4102-B2, BS 476, NF P 92 501-M1 |

| RESISTANCE TO CHEMICAL AGENTS ACC. TO ASTM 543-56 T | Very good |

| DIMENSIONAL STABILITY ACCORDING TO ISO 2796 FOR TEMPERATURES UP TO 1000C | <5% |

Values are listed, as obtained under standard laboratory conditions and may be amended, without prior notice.

| COPPER TUBE EXTERNAL DIAMETER (mm) | COPPER TUBE WALL THICKNESS (mm) | OVERALL EXTERNAL DIAMETER WITH 9mm THICK INSULATION (mm) |

|---|---|---|

| 6 | 0,80 | 24 |

| 8 | 0,80 | 26 |

| 10 | 0,80 | 28 |

| 12 | 1,00 | 30 |

| 15 | 1,00 | 33 |

| 16 | 1,00 | 34 |

| 18 | 1,00 | 36 |

| 22 | 1,00 | 40 |

| COPPER TUBE EXTERNAL DIAMETER INCH | COPPER TUBE EXTERNAL DIAMETER MM | COPPER TUBE WALL THICKNESS MM | OVERALL EXTERNAL DIAMETER WITH 9MM THICK INSULATION MM |

|---|---|---|---|

| 1/4-3/8 | 6,35-9,52 | 0,80-0,80 | 24,4-27,5 |

| 1/4-1/2 | 6,35-12,7 | 0,80-0,80 | 24,4-30,7 |

| 1/4-5/8 | 6,35-15,88 | 0,80-1,00 | 24,4-33,9 |

| 1/4-3/4 | 6,35-19,05 | 0,80-1,00 | 24,4-37,10 |

| 3/8-1/2 | 9,52-12,7 | 0,80-0,80 | 27,5-30,7 |

| 3/8-5/8 | 9,52-15,88 | 0,80-1,00 | 27,5-33,9 |

| 3/8-3/4 | 9,52-19,05 | 0,80-1,00 | 27,5-37,1 |

| 1/2-3/4 | 12,7-19,05 | 0,80-1,00 | 30,7-37,1 |

Learn more about the product

Discover our quality marks:

TALOS® XS tubes are manufactured using a high strength copper-alloy (CuFe2P) material, in order to satisfy the demands of today’s high-pressure CO₂ systems in refrigeration, as well as, other high-pressure HVAC&R applications.

CO₂ (R-744) refrigerant is termed a “natural” refrigerant because it exists in the natural environment. Released from refrigeration systems into the atmosphere, CO₂ has a negligible effect to global warming and thus is not under any regulatory restrictions, as is the case for CFC, HCFC and HFC refrigerants.

In addition to its environmental-friendly character, CO₂ is currently viewed as a viable solution for low-temperature refrigeration applications because it is non-ozone depleting, non-toxic, non-flammable and has a high volumetric cooling capacity. However due to its physical properties, CO₂ based refrigeration systems request much higher pressure, compared to conventional systems. The design pressure of such systems can be 120/130bar in the trans-critical cycle. CO₂ meets the demand for a low-global warming potential (GWP) refrigerant, but presents challenges in both its application and handling. The higher operating pressure and broad temperature fluctuations require that all the system components, including piping, should be designed accordingly.

TALOS® XS tubes are designed to withstand high operating pressures of up to 120/130bar. At the same time, TALOS® XS tubes are manufactured with comparatively thinner walls and thus achieve an economical advantage that meets the pressure equipment design. The well-known installation practices of refrigeration copper tubes are followed also for the case of TALOS® XS tubes, both in systems and in the field (see relative EN378 standard for guidelines). Since the processing methodology remains essentially the same, existing tooling and handling equipment are utilized. This includes brazing with standardized silver braze alloy (min. silver content of 2%), bending with traditional tools and joining with standardized fittings made from copper alloy (CuFe2P).

Copper-iron alloy (CuFe2P) with chemical composition according to EN 12735-1 (CW107C) and UNS C19400

| Outside Diameter | Wall Thickness | Temper | ||||

|---|---|---|---|---|---|---|

| 120bar1 | 130bar1 | |||||

| (mm) | (inch) | (mm) | (inch) | (mm) | (inch) | |

| 9.52 | 3 / 8″ | 0.56 | 0.022 | 0.65 | 0.026 | R300 |

| 12.7 | 1 / 2″ | 0.75 | 0.030 | 0.85 | 0.033 | R300 |

| 15.87 | 5 / 8″ | 0.93 | 0.037 | 1.05 | 0.041 | R300 |

| 19.05 | 3 / 4″ | 1.19 | 0.046 | 1.30 | 0.051 | R300 |

| 22.23 | 7 / 8″ | 1.38 | 0.054 | 1.50 | 0.059 | R300 |

| 28.57 | 1 1 / 8″ | 1.78 | 0.070 | 1.90 | 0.075 | R300 |

| 34.92 | 1 3 / 8″ | 2.17 | 0.085 | 2.30 | 0.091 | R300 |

| 41.27 | 1 5 / 8″ | 2.56 | 0.100 | 2.70 | 0.106 | R300 |

| 53.97 | 2 1 / 8″ | 3.35 | 0.131 | 3.55 | 0.140 | R300 |

| 66.67 | 2 5 / 8″ | 4.14 | 0.163 | 4.45 | 0.175 | R300 |

1 Maximum Allowable Pressure of 120bar (1740psi) and 130bar (1885psi) up to 150°C (302°F) and down to -196°C (-320°F) calculated acc. to EN14276:2020.

Learn more about our product:

Discover our quality marks:

Our product range is designed with a commitment to excellence, delivering unmatched durability and efficiency to meet your needs. Engineered for reliability and performance, each product offers exceptional value, ensuring long-lasting solutions that enhance your experience. Whether you’re seeking practicality or innovation, our range provides reliable results you can count on every time.

Copper phosphorus deoxidised (Cu-DHP), having minimum copper content 99,90% and P = 0,015% – 0,040%.

EN 12735 parts 1 & 2, ASTM B280/B68/B743, JIS H3300

TALOS® ACR copper tubes produced according to EN 12735 parts 1 & 2 are certified according to the requirements of the Pressure Equipment Directive (PED) 2014/68/EU, as well as, the German regulation AD2000/W6 for pressure vessels.

AENOR, TÜV, GL, VIK.

| Material Condition Designation Temper | Minimum Tensile strength Rm (MPa) | Min elongation, A% |

|---|---|---|

| Annealed | 220 | 40 |

| Half Hard | 250 | 30 |

| Hard | 290 | 3 |

| Temper | Minimum Tensile strength Rm (MPa) | Yield strength, Rp0.2 (MPa) | Min elongation, A% |

|---|---|---|---|

| Soft Annealed | 210 | 35-80 | >40% |

| Light Annealed | 220 | 40-90 | >40% |

| Half Hard | 250 | – | >30% |

| Hard | 290 | – | >3% |

PANCAKES (SOFT)

| COPPER TUBE EXTERNAL DIAMETER MM | COPPER TUBE WALL THICKNESS MM | WEIGHT KGR/M |

|---|---|---|

| 4,76 | 0,80 | 0,089 |

| 6,35 | 0,80 | 0,124 |

| 7,94 | 0,80 | 0,160 |

| 9,52 | 0,80 | 0,195 |

| 12,70 | 0,80 | 0,266 |

| 15,88 | 1,00 | 0,416 |

| 19,05 | 1,00 | 0,505 |

| 22,23 | 1,00 | 0,594 |

STRAIGHT LENGTHS (5 METERS)

| COPPER TUBE EXTERNAL DIAMETER MM | COPPER TUBE WALL THICKNESS MM | WEIGHT KGR/M |

|---|---|---|

| 9,52 | 0,75 | 0,184 |

| 12,70 | 0,80 | 0,266 |

| 15,88 | 0,80 | 0,337 |

| 19,05 | 0,80 | 0,408 |

| 22,23 | 1,00 | 0,594 |

| 28,58 | 1,00 | 0,771 |

| 34,93 | 1,25 | 1,177 |

| 41,28 | 1,25 | 1,399 |

| 53,98 | 1,65 | 2,414 |

| 66,68 | 2,00 | 3,617 |

| 79,38 | 2,30 | 4,957 |

| 92,08 | 2,50 | 6,262 |

| 104,78 | 2,85 | 8,122 |

Customized dimensions are manufactured upon request.

PANCAKES (SOFT TEMPER)

| COPPER TUBE EXTERNAL DIAMETER INCH | COPPER TUBE EXTERNAL DIAMETER MM | COPPER TUBE WALL THICKNESS INCH | COPPER TUBE WALL THICKNESS MM | WEIGHT KGR/M |

|---|---|---|---|---|

| 3/16 | 4,76 | 0,030 | 0,76 | 0,085 |

| 1/4 | 6,35 | 0,030 | 0,76 | 0,119 |

| 5/16 | 7,94 | 0,032 | 0,81 | 0,162 |

| 3/8 | 9,52 | 0,032 | 0,81 | 0,198 |

| 1/2 | 12,70 | 0,032 | 0,81 | 0,270 |

| 5/8 | 15,88 | 0,035 | 0,89 | 0,372 |

| 3/4 | 19,05 | 0,035 | 0,89 | 0,451 |

| 7/8 | 22,23 | 0,045 | 1,14 | 0,672 |

STRAIGHT LENGTHS (HARD TEMPER, 4 OR 5 METERS)

| COPPER TUBE EXTERNAL DIAMETER INCH | COPPER TUBE EXTERNAL DIAMETER MM | COPPER TUBE WALL THICKNESS INCH | COPPER TUBE WALL THICKNESS MM | WEIGHT KGR/M |

|---|---|---|---|---|

| 3 / 8 | 9,52 | 0,030 | 0,76 | 0,187 |

| 1 / 2 | 12,70 | 0,035 | 0,89 | 0,294 |

| 5 / 8 | 15,88 | 0,040 | 1,02 | 0,424 |

| 3 / 4 | 19,05 | 0,042 | 1,07 | 0,538 |

| 7 / 8 | 22,23 | 0,045 | 1,14 | 0,672 |

| 1.1/ 8 | 28,56 | 0,050 | 1,27 | 0,970 |

| 1.3/ 8 | 34,93 | 0,055 | 1,40 | 1,312 |

| 1.5/ 8 | 41,28 | 0,060 | 1,52 | 1,690 |

| 2.1/ 8 | 53,98 | 0,070 | 1,78 | 2,598 |

| 2.5/ 8 | 66,68 | 0,080 | 2,03 | 3,669 |

| 3.1/ 8 | 79,38 | 0,090 | 2,29 | 4,936 |

| 3.5/ 8 | 92,08 | 0,100 | 2,54 | 6,359 |

| 4.1/ 8 | 104,78 | 0,110 | 2,79 | 7,956 |

Customized dimensions are manufactured upon request.

Straight lengths, in bundles (hard copper tubes) and in wooden boxes (soft copper tubes) Pancakes-PNC in shrink-wrapped individual plastic bags. Depending on market requirements, products can be placed in cardboard boxes and pallets. Customised dimensions are manufactured upon request.

TALOS® ACR copper tubes for HVAC & R units are available in the following forms:

Spools (LWC)

TALOS® ACR copper tubes are available in spools (LWC) with or without central support (hard carton). Spool sides may be delivered protected by “flanges” of reinforced cardboard.

“CD” coils: Spools with a “central” decoiling

Spools with a “central” decoiling are especially prepared so that unwinding from the center of the coil is possible. They provide significant advantages to the user, such as reduction in packaging materials, unwinding directly from the pallet and greater weights per spool. “CD” coils of TALOS® ACR copper tubes do not require special unwinding equipment; they have lower handling costs, reducing machine downtime and increasing production efficiency.

| EXTERNAL DIAMETER | INCH – MM | 5/16 – 7,94 | 3/8 – 9,52 | 1/2 – 12,70 | 5/8 – 15,87 |

|---|---|---|---|---|---|

| Thickness (inch) (mm) | 0,011 0,28 | X | X | ||

| Thickness (inch) (mm) | 0,012 0,30 | X | X | ||

| Thickness (inch) (mm) | 0,014 0,35 | X | X | X | |

| Thickness (inch) (mm) | 0,016 0,41 | X | X | X | X |

| Thickness (inch) (mm) | 0,018 0,45 | X | X | X | |

| Thickness (inch) (mm) | 0,020 0,51 | X | X | X | |

| Thickness (inch) (mm) | 0,025 0,635 | X | X | ||

| Thickness (inch) (mm) | 0,028 0,71 | X | X | X |

| SPOOL WEIGHT kg | FORM OF SUPPLY |

|---|---|

| 75 | With or without carton spool |

| 85 | With or without carton spool |

| 115 | With or without carton spool |

| 150 | With or without carton spool |

| 200 | With or without carton spool |

| 290 | Without carton spool |

| 460 | Without carton spool |

| 580 | Without carton spool |

Learn more about our product:

Discover our quality marks:

Our product range is designed with a commitment to excellence, delivering unmatched durability and efficiency to meet your needs. Engineered for reliability and performance, each product offers exceptional value, ensuring long-lasting solutions that enhance your experience. Whether you’re seeking practicality or innovation, our range provides reliable results you can count on every time.

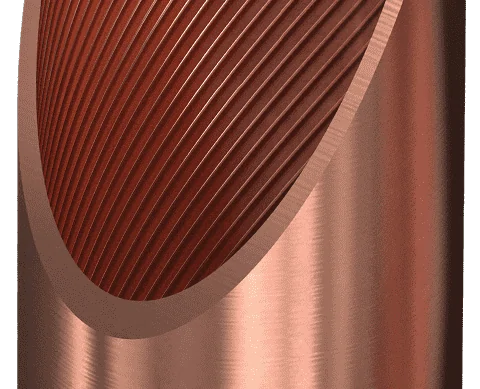

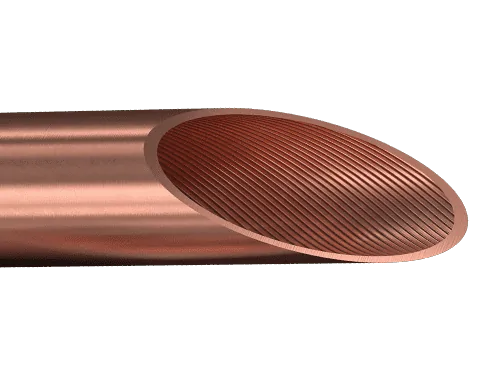

TALOS®IGT copper tubes feature inner grooves that enhance the heat transferred by the refrigerant and as a result increase the energy efficiency of the HVACR units. Applications of TALOS® IGT include heat exchangers for condensation and/or evaporation in A/C and refrigeration systems, as well as, heat pumps.

HALCOR’s production technology for TALOS® IGT copper tubes enables the manufacture of advanced inner-groove designs for a complete range of sizes, starting from 16mm outside diameter down to the new generation microgrooveTM tubes with an outside diameter of 5mm or less, being one of the few manufacturers worldwide to have this capability.

The ability of Halcor to provide complete solutions to its clients was reinforced by the establishment of a Tube Heat Transfer Laboratory. The equipment of the Tube Heat Transfer Laboratory was specially designed to enable measurements of the heat transfer performance of ACR tubes under fully controlled test conditions. Critical features, such as, the heat transfer co-efficient and the pressure drop, are measured using a sophisticated system for condensation and evaporation of HFC and natural refrigerants, as well as, single-phase fluids and fluid mixtures. The flow and thermal parameters are programmed to simulate specific operating conditions, such as, refrigerant flow rate, saturation temperature, vapor quality, thermal capacity, etc. and thus allow Halcor’s engineers to study the influence of the inner-groove design.

The Tube Heat Transfer Laboratory gives Halcor the capability to incorporate the test results in a complete framework of technical support to manufacturers of heat-exchangers, with the purpose of optimizing their heat-exchanger design for any of the following:

| External diameter D (mm) | Bottom wall thickness tb (mm) | Groove depth h (mm) | Top angle γ (deg) | Lead angle φ (deg) | Number of grooves n | Unit weight(g/m) |

|---|---|---|---|---|---|---|

| 5,00 | 0,20-0,23 | 0,12-0,15 | 11-40 | 18-40 | 40-58 | 32-35 |

| 6,35 | 0,23-0,27 | 0,15-0,16 | 12-40 | 18-28 | 45-54 | 46-53 |

| 7,00 | 0,21-0,27 | 0,10-0,24 | 10-53 | 15-40 | 50-70 | 46-60 |

| 7,94 – 8,00 | 0,23-0,41 | 0,12-0,22 | 12-42 | 18-43 | 50-80 | 57-69 |

| 9,52 | 0,27-0,45 | 0,15-0,25 | 20-90 | 15-30 | 55-85 | 80-128 |

| 11,90-12,00 | 0,32-0,40 | 0,17-0,25 | 15-55 | 16-30 | 70-98 | 120-145 |

| 12,70 | 0,32-0,41 | 0,23-0,25 | 30-58 | 18-30 | 70-75 | 135-170 |

| 15,00 – 15,90 | 0,35-0,50 | 0,25-0,35 | 30-53 | 18-30 | 30-75 | 188-259 |

Learn more about the product

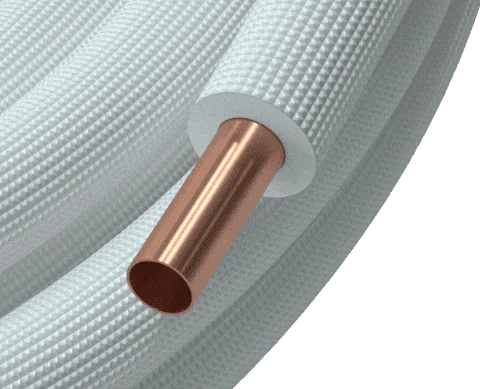

Our ECUTHERM product range combines durability with energy efficiency, utilizing advanced PEX (cross-linked polyethylene) technology to deliver long-lasting performance and significant energy savings. Key benefits of the ECUTHERM series include thermal insulation properties, reducing energy consumption while maintaining exceptional strength and durability. Its resistance to moisture and chemicals makes it an excellent choice for challenging environments and demanding conditions.

Copper phosphorus deoxidised (Cu-DHP) with min. copper content 99,90% and Ρ=0,015% – 0,040%.

REFRIGERATION PIPES: EN 12735-1.

REFRIGERATION PIPES: AENOR, TÜV, GL, VIK.

| Temper | EN 12735 Classification | Minimum Tensile strength Rm (MPa) | Min elongation, A% |

|---|---|---|---|

| Soft | R-220 | 220 | 40 |

| MATERIAL | PE-X or PE foam |

| DENSITY ACCORDING TO DIN 53420 ASTM D 1667 | 30-33 Kg/m3 |

| THERMAL CONDUCTIVITY COEFFICIENT (λ) ACCORDING TO EN ISO 8497 | 0.0357 W/mK (0oC)0,0389 W/mK (40oC)​ |

| VAPOUR-WATER DIFFUSSION RESISTANCE COEFFICIENT (μ) ACCORDING TO EN 13469 | 12.500 |

| WORKING TEMPERATURE | -80oC to +110oC(+90oC for PE foam) |

| FIRE RESISTANCE | EN 13501–1, Class B or Class E, DIN 4102, B2, BS 476, NF P 92 501-M1 |

| RESISTANCE TO CHEMICAL AGENTS ACC. TO ASTM 543-56 T | Very good |

| DIMENSIONAL STABILITY ACCORDING TO ISO 2796 FOR TEMPERATURES UP TO 1000C | <5% |

| COPPER TUBE EXTERNAL DIAMETER INCH | COPPER TUBE EXTERNAL DIAMETER MM | COPPER TUBE WALL THICKNESS MM | OVERALL EXTERNAL DIAMETER WITH 9MM THICK INSULATION MM |

|---|---|---|---|

| 3/16 | 4,76 | 0,80 | 22,76 |

| 1/4 | 6,35 | 0,80 | 24,35 |

| 5/16 | 7,94 | 0,80 | 25,94 |

| 3/8 | 9,52 | 0,80 | 25,72 |

| 1/2 | 12,70 | 0,80 | 30,70 |

| 5/8 | 15,87 | 1,00 | 33,87 |

| 3/4 | 19,05 | 1,00 | 37,05 |

| 7/8 | 22,23 | 1,00 | 40,23 |

Maximum Working Pressure calculation according to EN 14276:2020 which complies with e European Directive PED 2014/68/EU (Pressure Equipment Directive).