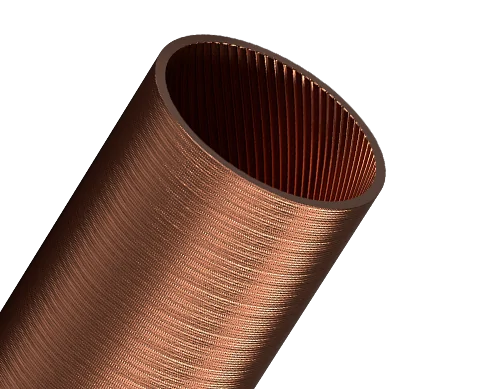

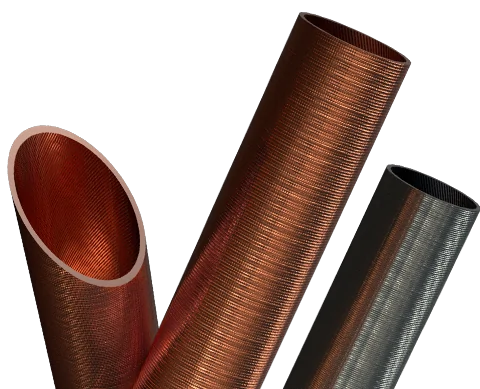

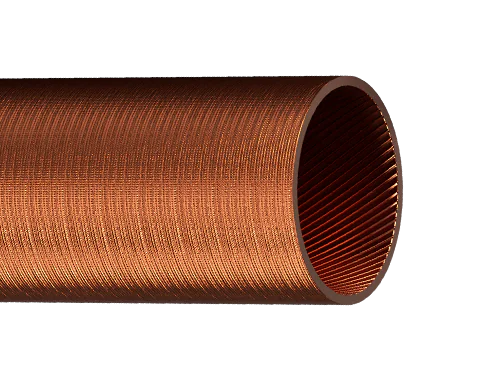

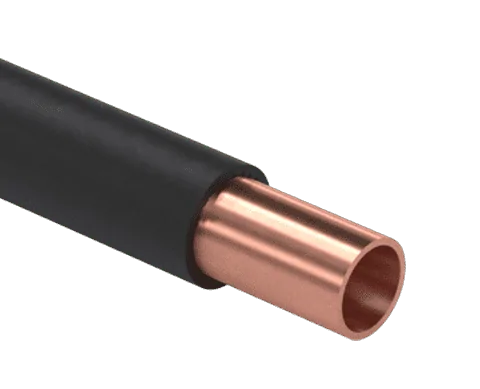

TALOS® FIN

TALOS® FIN copper tubes are advanced technological products of high added value and significantly superior in effectiveness compared to conventional insulation methods.

Copper Tube Material/Alloys

Copper phosphorus deoxidised (DHP-Cu) with min. copper content 99,90% and Ρ=0,015% – 0,040%.

Introducing our new joint venture, HALCOR-NTT, as a synergy of leadership and technical expertise, we have the vision to revolutionize the HVACR market.

Our company, driven by the motto “Engineering Thermal Innovation,” combines the strengths of a leading European manufacturer with the innovative capabilities of a recognized technical expert. This partnership ensures a comprehensive range of engineered products that are designed, tested and produced within Europe, tailored to meet the diverse needs of the European market for technical tubing. Together, we are committed to delivering superior quality, cutting-edge technology, and unparalleled service, setting new standards in thermal engineering excellence.

CUSMART®

Our product range is designed with a commitment to excellence, delivering unmatched durability and efficiency to meet your needs. Engineered for reliability and performance, each product offers exceptional value, ensuring long-lasting solutions that enhance your experience. Whether you’re seeking practicality or innovation, our range provides reliable results you can count on every time.

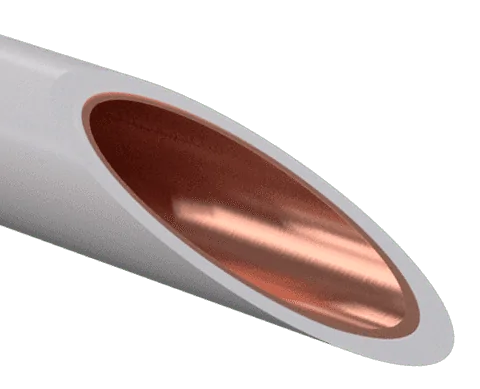

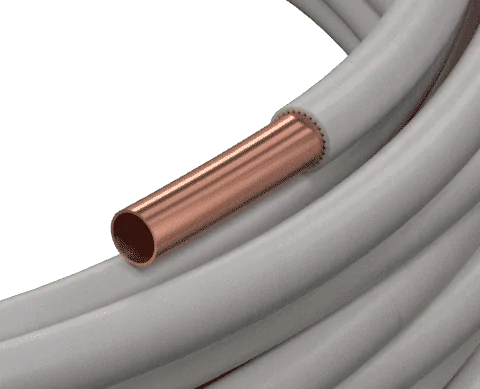

CUSMART® flexible copper tubes are unsurpassed in every technical aspect, offering great installation ease. Their exceptional flexibility allows cold bending and even manual shaping without “memory” effects. The use of CUSMART®flexible copper tubes in plumbing, cuts down on installation time and cost, offering uncompromised security.

CUSMART® flexible copper tubes are patented flexible copper tubes with a special compound coating. They preserve their physical and technical properties throughout their lifetime and are covered by a 20-year manufacturer’s guarantee.

CUSMART® superiority in every aspect

- Long lifetime

- A special process that ensures hygiene

- High pressure and temperature fluctuation resistance

- Unique flexibility and final shape stability

- Exceptional thermal conductivity

- Minimum thermal expansion

- Cost-effective system

- Impermeability – 100% Oxygen Barrier

- Recyclable product

- UV resistance and maximum corrosion resistance

- Significant energy savings with industrial insulation

Product Description

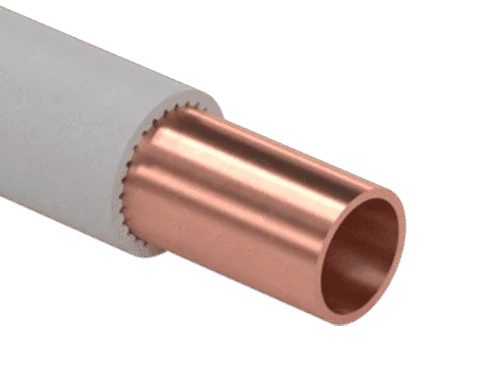

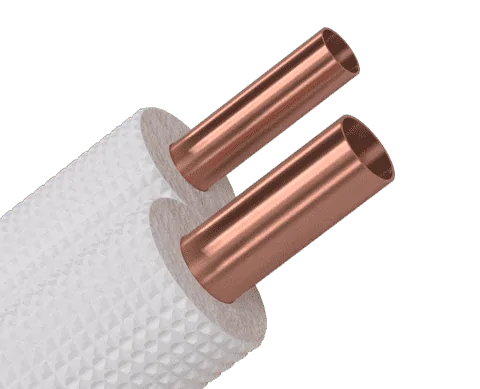

CUSMART® flexible copper tubes are coated with a special white colored compound for enhanced endurance at temperatures up to 95 oC.

Quality Marks

RAL, NSF*.

* Only products bearing the NSF Mark on the product, product packaging, and/or documentation shipped with the product are certified.

| Temper | Minimum Tensile strength Rm (MPa) | Min elongation, A% |

|---|---|---|

| Soft | 220 | 40 |

STRAIGHT HALF HARD

| NOMINAL DIMENSIONS (MM) | OUTSIDE DIAMETER – (OD)(MM) | WALL THICKNESS (MM) | INSIDE DIAMETER (ID)(MM) | INSIDE DIAMETER CROSS-SECTION (CM2) | WATER VOLUME (L/M) | MAXIMUM WORKING TEMPERATURE (OC) | THERMAL CONDUCTIVITY COEFFIENT W/(M*OK) | MINIMUM BENDING RADIUS WITH BENDING TOOL (MM) | MINIMUM BENDING RADIUS WITH EXTERNAL BENDING SPRING=4X OD(MM) | BENDING RADIUS MANUAL =6X OD(MM) | PACKAGING STRAIGHT LENGTHS | PACKAGING COILS (M) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 14Χ2 | 14 | 2 | 10 | 0,785 | 0,0785 | 95 | 0,4 | 39 | 56 | 84 | 3 | 100/ 50 |

| 16Χ2 | 16 | 2 | 12 | 1,131 | 0,1131 | 95 | 0,4 | 45 | 64 | 96 | 3 | 100/ 50 |

| 18Χ2 | 18 | 2 | 14 | 1,5 | 0,154 | 95 | 0,4 | 53 | 72 | 108 | 3 | 100/ 50 |

| 20Χ2 | 20 | 2 | 16 | 2,011 | 0,2011 | 95 | 0,4 | 64 | 80 | 120 | 3 | 100/ 50 |

| 26Χ3 | 26 | 3 | 20 | 3,142 | 0,3142 | 95 | 0,4 | 89 | 104 | 156 | 3 | 25/ 50 |

| 32Χ3 | 32 | 3 | 26 | 5,309 | 0,5309 | 95 | 0,4 | 128 | 128 | 192 | 3 | 25 |

Different dimensions and lengths are available upon request.

| NOMINAL DIMENSION (MM) | TOTAL OUTSIDE DIAMETER (INSULATION THICKNESS: 9 MM) | PACKAGING – COIL (M) |

|---|---|---|

| 14X2 | 32 | 100/ 50 |

| 16X2 | 34 | 100/ 50 |

| 18X2 | 36 | 100/ 50 |

| 20X2 | 38 | 100/ 50 |

| 26X3 | 44 | 25/ 50 |

| 32X3 | 50 | 25 |

CUSMART® flexible tubes with external industrial insulation are suitable for all heating and hot water supply plumbing networks inside and outside buildings. The insulation is a cross-linked polyethylene (PE-X) foam structured in closed type microcells. Energy saving is a result of the spectacular reduction of temperature loss to over 50% compared to similar networks without insulation.

The CUSMART® all-inclusive flexible copper tube system includes a full range of CUSMART FITTINGS (press and compression fittings), as well as tools, ensuring reliable results in every application.

| MATERIAL | PE-X or PE foam |

| DENSITY ACCORDING TO DIN 53420 ASTM D 1667 | 30-33 Kg/m3 |

| THERMAL CONDUCTIVITY COEFFICIENT (λ) ACCORDING TO EN ISO 8497 | 0.0357 W/mK (0oC)0,0389 W/mK (40oC) |

| VAPOUR-WATER DIFFUSSION RESISTANCE COEFFICIENT (μ) ACCORDING TO EN 13469 | 12.500 |

| WORKING TEMPERATURE | -80oC to +110oC(+90oC for PE foam) |

| FIRE RESISTANCE | EN 13501–1, Class B or Class E, DIN 4102, B2, BS 476, NF P 92 501-M1 |

| RESISTANCE TO CHEMICAL AGENTS ACC. TO ASTM 543-56 T | Very good |

| DIMENSIONAL STABILITY ACCORDING TO ISO 2796 FOR TEMPERATURES UP TO 1000C | <5% |

Values are listed, as obtained under standard laboratory conditions and may be amended, without prior notice.

TALOS® LPG

Our product range is designed with a commitment to excellence, delivering unmatched durability and efficiency to meet your needs.

Automotive liquefied petroleum gas or autogas is a term broadly used for liquefied petroleum gas (LPG), when used for land vehicle propulsion. The calorific value of LPG is similar to that of petrol, and thanks to this property, it constitutes an excellent automotive fuel. The main ingredients of autogas are propane gas (C3H8) and butane gas (C4H10). Subsequent to the recent adoption of European Regulation ECE-R67, Halcor developed TALOS® LPG copper tubes for LPG vehicle use. These tubes are successfully subjected to especially stringent tests.

| Product State | Notation per EN 1057 | Minimum burst load N/mm2 | Minimum elongation A% |

|---|---|---|---|

| Soft | R-220 | 220 | 40 |

Construction material

PIPE:

Phosphor deoxidised copper (DHP-Cu)

PLASTIC COATING

High Thermal Strength Polyethylene (PE-RT), or Polyvinyl Chloride (PVC). Maximum operating temperature 95°C

Specifications

EN 12449

TALOS® LPG copper tubes are manufactured according to the Harmonised European Specification ΕΝ 12449. Their plastic outer coating reduces heat losses, prevents burns to users, protects copper tubes against harsh environmental factors, and provides longer tube service life. The outer plastic coating is flexible and allows bending or other operations during installation.

TALOS® LPG copper tubes meet the requirements of ECΕ-R67, and also comply with the German Code AD 2000/W6 for pressurized containers.

| Outer copper tube diameter (mm)* | Copper tube wall thickness (mm)* | Weight (kg/m)** | Maximum permissible operating pressure (bar) |

|---|---|---|---|

| 6 | 0,8 | 0,116 | 142 |

| 6 | 0,9 | 0,128 | 162 |

| 6 | 1,0 | 0,140 | 183 |

| 8 | 0,8 | 0,161 | 104 |

| 8 | 0,9 | 0,179 | 118 |

| 8 | 1,0 | 0,196 | 133 |

* The values noted in the table refer to the outer diameter of the copper tube, excluding the plastic coating.

Coating thickness varies between 0,7 and 1,0 mm.

** Copper tube weight only (excluding plastic coating)

The maximum permissible operating pressure values are calculated for R200 material condition. The safety factor is considered equal to 3.5. Due to manufacturing tolerances, the minimum coating thickness is considered.Any treatment following product delivery is not taken into consideration. For operating temperatures up to 100°C inclusive.

MEDIA FILES

Brochures

Learn more about the product

TALOS® COATED

Our product range is designed with a commitment to excellence, delivering unmatched durability and efficiency to meet your needs. Engineered for reliability and performance, each product offers exceptional value, ensuring long-lasting solutions that enhance your experience. Whether you’re seeking practicality or innovation, our range provides reliable results you can count on every time.

Material

Copper phosphorus deoxidised (DHP-Cu) with min. copper content 99,90% and Ρ=0,015% – 0,040%.

Specifications

Copper Tube: EN 13349, EN 1057

Plastic Sheathing: Classified as Class E according to EN 13501-1 fire resistance classification system.

Quality Marks

Copper tube: AFNOR, RAL / DVGW, BSI, AENOR, NSAI, DVGW, KIWA / GASTEC-QA, SITAC, STF VTT, GOST VIK..

| Temper | EN 13348 Classification | Minimum Tensile strength Rm (MPa) | Min elongation, A% |

|---|---|---|---|

| Soft | R-220 | 220 | 40 |

| Half hard | R-250 | 250 | 20 or 30* |

| Hard | R-290 | 290 | 3 |

*depending on the dimension

SOFT COILS

| Copper tube ext.diam. x thickness D x s (mm) | Overall ext. diameter D (mm) | Tube filling volume (l/m | Nominal copper weight (kg/m) | Thermal* capacity* (kcal/h) | Min. bending radius manually (m/m) | Min. bending radius with bending tool (m/m) | Packing in coils (m) long |

|---|---|---|---|---|---|---|---|

| 12Χ1,00 | 16 | 0,079 | 0,308 | 4.400 | 100 | – | 25 or 50 |

| 15X0,80 | 19 | 0,141 | 0,318 | 8.000 | 125 | – | 25 or 50 |

| 15Χ1,00 | 19 | 0,133 | 0,391 | 7.500 | 120 | – | 25 or 50 |

| 16X1,00 | 20 | 0,154 | 0,420 | 8.700 | 130 | – | 25 or 50 |

| 18X0,80 | 23 | 0,211 | 0,385 | 11.900 | 150 | – | 25 or 50 |

| 18Χ1,00 | 23 | 0,200 | 0,475 | 11.300 | 145 | – | 25 or 50 |

| 22Χ1,00 | 27 | 0,315 | 0,537 | 17.700 | 175 | – | 25 |

STRAIGHT HARD

| Copper tube ext.diam. x thickness D x s (mm) | Overall ext. diameter D (mm) | Tube filling volume (l/m) | Nominal copper weight (kg/m) | Thermal* capacity* (kcal/h) | Min. bending radius manually (m/m) | Min. bending radius with bending tool (m/m) | Packing in coils (m) long |

|---|---|---|---|---|---|---|---|

| 15Χ1,00 | 19 | 0,133 | 0,391 | 7.600 | – | 55 | Straight lengths of 4m |

| 16Χ1,00 | 20 | 0,154 | 0,420 | 8.600 | – | 60 | Straight lengths of 4m |

| 18Χ1,00 | 23 | 0,191 | 0,563 | 11.200 | – | 70 | Straight lengths of 4m |

| 22Χ1,00 | 27 | 0,314 | 0,857 | 17.400 | – | 80 | Straight lengths of 4m |

*For a temperature drop of 20oC and a flow rate of 0.8 m/sec.

TALOS® S80

Engineered for reliability and performance, each product offers exceptional value, ensuring long-lasting solutions that enhance your experience.

CO2 Subcritical Systems

Carbon dioxide (CO2) is a naturally occurring substance in the atmosphere and it has been used as refrigerant since the early days of refrigeration. CO2 has zero ODP and a GWP of 1, making it one of the best choices from an environmental perspective. Due to thermodynamic properties, CO2 systems require high operating pressures in order to operate efficiently. CO2 has a low critical temperature and high pressure 31°C and 73.8bar respectively.

CO2 refrigeration cycles can be transcritical as well as subcritical. Transcritical and subcritical refers to the high-pressure side of the systems, as it operates above or below the critical point, respectively. Transcritical refers to the state of the refrigerant above the critical point.

The design pressure of CO2 systems depends on the corresponding component refrigerant state. A design pressure of 80bar is sufficient for components in contact with non-transcritical CO2 at working and standstill conditions.

TALOS® S80

TALOS® S80 tubes are specifically designed for an operation pressure of up to 80bar. In order to meet the high-pressure CO2 requirements TALOS®S80 tubes are manufactured with reinforced wall thicknesses in comparison with TALOS® ACR.

TALOS® S80 can be used where the system’s design pressure does not exceed 80bar, i.e. where the CO2 is not supercritical. In practice, this occurs at both high and low pressure sides in subcritical cycles and at the low pressure side of transcritical cycles.

The well-known installation practices of refrigeration copper tubes apply both in systems and in the field (see relative EN378 standard for guidelines).

ΤALOS® S80 Product Features

- Tailored to meet subcritical CO2 systems requirements

- Suitable for ACR systems with a design pressure up to 80bar.

- Traditional processing techniques and equipment

- Excellent “cold formability”

- Smooth internal surface enhancing flow rate

- High purity of internal surface

- Stable mechanical properties covering an extensive temperature range

- Excellent brazing ability.

- Compatible with standardized ACR fittings.

Material

Copper phosphorus deoxidised (Cu-DHP), having minimum copper content 99,90% and P = 0,015% – 0,040%.

- Tailored to meet subcritical CO2 systems requirements

- Suitable for ACR systems with a design pressure up to 80bar.

- Traditional processing techniques and equipment

- Excellent “cold formability”

- Smooth internal surface enhancing flow rate

- High purity of internal surface

- Stable mechanical properties covering an extensive temperature range

- Excellent brazing ability.

- Compatible with standardized ACR fittings.

| TALOS®S80 for 80bar1 | |||

|---|---|---|---|

| Outer Diameter | Wall Thickness | ||

| [inch] | [mm] | [mm] | [inch] |

| 5/16” | 7,94 | 0,70 | 0,028 |

| 3/8” | 9,53 | 0,80 | 0,031 |

| 1/2” | 12,70 | 0,90 | 0,035 |

| 5/8” | 15,88 | 1,05 | 0,041 |

| 3/4” | 19,05 | 1,30 | 0,051 |

| 7/8” | 22,23 | 1,50 | 0,059 |

| 1 1/8” | 28,58 | 1,90 | 0,075 |

| 1 3/8” | 34,93 | 2,30 | 0,091 |

| 1 5/8” | 41,28 | 2,70 | 0,106 |

| 2 1/8” | 53,98 | 3,60 | 0,142 |

| 2 5/8” | 66,68 | 4,50 | 0,177 |

1. Maximum Allowable Pressure calculation acc. to EN 14276:2020. For service temperatures from -196°C up to 100°C.

Specifications

TALOS®S80 tubes are made from Copper-DHP (CW024A, UNS 12200). They are produced according to EN 12735-1 and internal production specifications and are approved according to the European Pressure Equipment Directive (PED) 2014/68/EU.

Form of supply

- Straight lengths, in bundles (hard copper tubes) and in wooden boxes (soft copper tubes).

- Pancakes-PNC in shrink-wrapped individual plastic bags. Depending on market requirements, products can be placed in cardboard boxes and pallets.

MEDIA FILES

Brochures

Learn more about the product

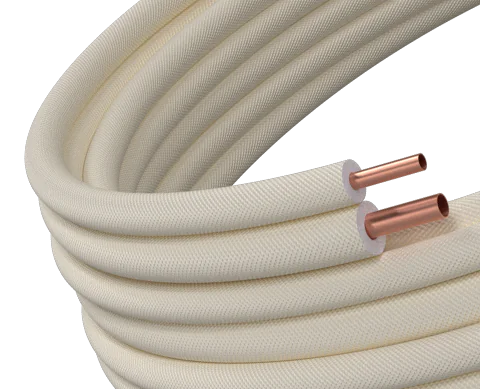

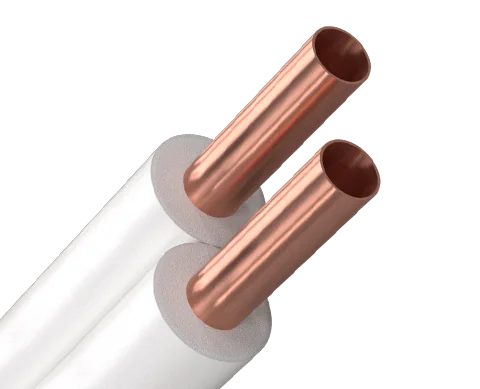

TALOS® ACR ECUTHERM II™

Our ECUTHERM product range combines durability with energy efficiency, utilizing advanced PEX (cross-linked polyethylene) technology to deliver long-lasting performance and significant energy savings.

Copper Tube Material

Copper phosphorus deoxidised (DHP-Cu), having minimum copper content 99,90% and P=0,015% – 0,040%.

Quality Marks

REFRIGERATION PIPES: ΑΕΝΟR TÜV, GL, VIK.

| Temper | EN 12735 Classification | Minimum Tensile strength Rm (MPa) | Min elongation, A% |

|---|---|---|---|

| Soft | R-220 | 220 | 40 |

| MATERIAL | PE-X or PE foam |

| DENSITY ACCORDING TO DIN 53420 ASTM D 1667 | 30-33 Kg/m3 |

| THERMAL CONDUCTIVITY COEFFICIENT (λ) ACCORDING TO EN ISO 8497 | 0.0357 W/mK (0oC)0,0389 W/mK (40oC)​ |

| VAPOUR-WATER DIFFUSSION RESISTANCE COEFFICIENT (μ) ACCORDING TO EN 13469 | 12.500 |

| WORKING TEMPERATURE | -80oC to +110oC(+90oC for PE foam) |

| FIRE RESISTANCE | EN 13501–1, Class B or Class E, DIN 4102, B2, BS 476, NF P 92 501-M1 |

| RESISTANCE TO CHEMICAL AGENTS ACC. TO ASTM 543-56 T | Very good |

| DIMENSIONAL STABILITY ACCORDING TO ISO 2796 FOR TEMPERATURES UP TO 1000C | <5% |

Values are listed, as obtained under standard laboratory conditions and may be amended, without prior notice.

| COPPER TUBE EXTERNAL DIAMETER INCH | COPPER TUBE EXTERNAL DIAMETER MM | COPPER TUBE WALL THICKNESS MM | OVERALL EXTERNAL DIAMETER WITH 9MM THICK INSULATION MM |

|---|---|---|---|

| ¼-3/8 | 6,35-9,52 | 0,80-0,80 | 24,4-27,5 |

| ¼-1/2 | 6,35-12,7 | 0,80-0,80 | 24,4-30,7 |

| ¼-5/8 | 6,35-15,88 | 0,80-1,00 | 24,4-33,9 |

| ¼-3/4 | 6,35-19,05 | 0,80-1,00 | 24,4-37,10 |

| 3/8-1/2 | 9,52-12,7 | 0,80-0,80 | 27,5-30,7 |

| 3/8-5/8 | 9,52-15,88 | 0,80-1,00 | 27,5-33,9 |

| 3/8-3/4 | 9,52-19,05 | 0,80-1,00 | 27,5-37,1 |

| ½-3/4 | 12,7-19,05 | 0,80-1,00 | 30,7-37,1 |

Other sizes and special packaging in pallets or cardboard boxes are available upon request.

Maximum Working Pressure calculation according to EN 14276:2020 which complies with e European Directive PED 2014/68/EU (Pressure Equipment Directive).

1/4″ + 3/8″

1/4″ + 1/2″

1/4″ + 5/8″

1/4″ + 3/4″

3/8″ + 1/2″

3/8″ + 5/8″

3/8″ + 3/4″

1/2″ + 3/4″

Appropriate also for the new Green Refrigeration Units

According to the European Standard EN12735-1:2010, as well as current market requirements, laid down by the use of new generation of refrigerants, including HFCs and HFOs, adopted by all major manufacturers of refrigeration and air conditioning units the following standardisation is applied to TALOS® ACR ECUTHERM 2TM copper tubes:

- For an external diameter of 1/4” to 1/2”, the wall thickness is standardised at 0,80 mm

- For an external diameter of 5/8” to 3/4”, the wall thickness is standardised at 1,00 mm

MEDIA FILES

Brochures

Learn more about the product