Brochures

Learn more about our product:

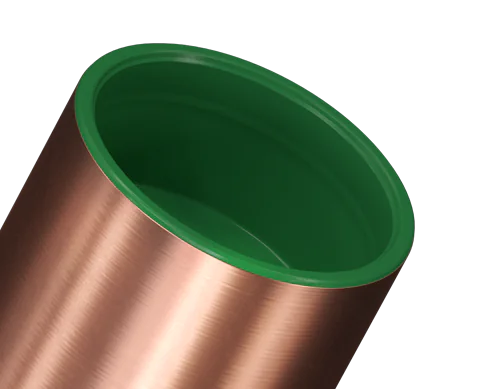

TALOS® XS tubes are manufactured using a high strength copper-alloy (CuFe2P) material, in order to satisfy the demands of today’s high-pressure CO₂ systems in refrigeration, as well as, other high-pressure HVAC&R applications.

CO₂ (R-744) refrigerant is termed a “natural” refrigerant because it exists in the natural environment. Released from refrigeration systems into the atmosphere, CO₂ has a negligible effect to global warming and thus is not under any regulatory restrictions, as is the case for CFC, HCFC and HFC refrigerants.

In addition to its environmental-friendly character, CO₂ is currently viewed as a viable solution for low-temperature refrigeration applications because it is non-ozone depleting, non-toxic, non-flammable and has a high volumetric cooling capacity. However due to its physical properties, CO₂ based refrigeration systems request much higher pressure, compared to conventional systems. The design pressure of such systems can be 120/130bar in the trans-critical cycle. CO₂ meets the demand for a low-global warming potential (GWP) refrigerant, but presents challenges in both its application and handling. The higher operating pressure and broad temperature fluctuations require that all the system components, including piping, should be designed accordingly.

TALOS® XS tubes are designed to withstand high operating pressures of up to 120/130bar. At the same time, TALOS® XS tubes are manufactured with comparatively thinner walls and thus achieve an economical advantage that meets the pressure equipment design. The well-known installation practices of refrigeration copper tubes are followed also for the case of TALOS® XS tubes, both in systems and in the field (see relative EN378 standard for guidelines). Since the processing methodology remains essentially the same, existing tooling and handling equipment are utilized. This includes brazing with standardized silver braze alloy (min. silver content of 2%), bending with traditional tools and joining with standardized fittings made from copper alloy (CuFe2P).

Copper-iron alloy (CuFe2P) with chemical composition according to EN 12735-1 (CW107C) and UNS C19400

| Outside Diameter | Wall Thickness | Temper | ||||

|---|---|---|---|---|---|---|

| 120bar1 | 130bar1 | |||||

| (mm) | (inch) | (mm) | (inch) | (mm) | (inch) | |

| 9.52 | 3 / 8″ | 0.56 | 0.022 | 0.65 | 0.026 | R300 |

| 12.7 | 1 / 2″ | 0.75 | 0.030 | 0.85 | 0.033 | R300 |

| 15.87 | 5 / 8″ | 0.93 | 0.037 | 1.05 | 0.041 | R300 |

| 19.05 | 3 / 4″ | 1.19 | 0.046 | 1.30 | 0.051 | R300 |

| 22.23 | 7 / 8″ | 1.38 | 0.054 | 1.50 | 0.059 | R300 |

| 28.57 | 1 1 / 8″ | 1.78 | 0.070 | 1.90 | 0.075 | R300 |

| 34.92 | 1 3 / 8″ | 2.17 | 0.085 | 2.30 | 0.091 | R300 |

| 41.27 | 1 5 / 8″ | 2.56 | 0.100 | 2.70 | 0.106 | R300 |

| 53.97 | 2 1 / 8″ | 3.35 | 0.131 | 3.55 | 0.140 | R300 |

| 66.67 | 2 5 / 8″ | 4.14 | 0.163 | 4.45 | 0.175 | R300 |

1 Maximum Allowable Pressure of 120bar (1740psi) and 130bar (1885psi) up to 150°C (302°F) and down to -196°C (-320°F) calculated acc. to EN14276:2020.

Learn more about our product:

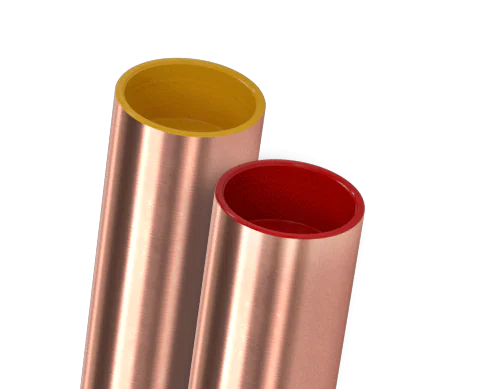

Discover our quality marks: