TALOS® ACR LINESETS

Our product range is designed with a commitment to excellence, delivering unmatched durability and efficiency to meet your needs. Engineered for reliability and performance, each product offers exceptional value, ensuring long-lasting solutions that enhance your experience.

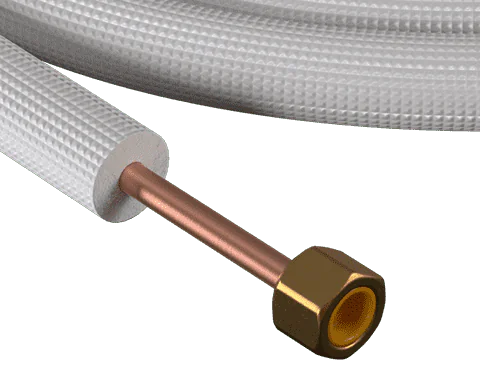

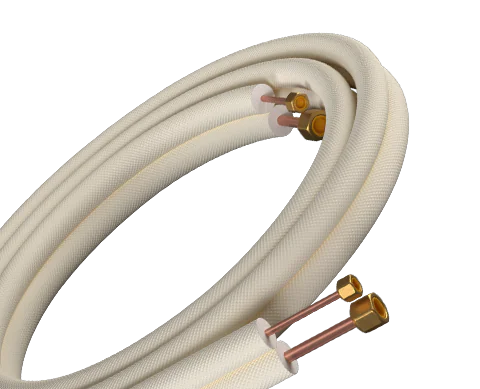

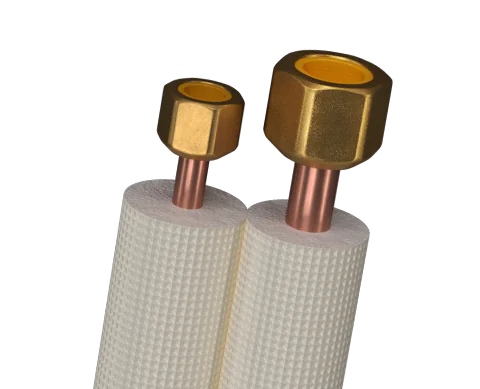

TALOS® ACR Linesets are designed especially for the split Air-Conditioning and Heat Pump Systems products requiring installation with flared connections. The unique advantages offered by TALOS® ACR Linesets, including, copper resistance and durability, high performance foam insulation and pre-flared ends with mounted flare nuts, result in significant energy savings and in quick, cost effective field installations.

Copper Tube Material

Copper phosphorus deoxidised (DHP-Cu) with min. copper content 99,90% and P=0,015% – 0,040%.

Specifications

REFRIGERATION PIPES: EN 12735-1

FOAM INSULATION: EN 13501-1

FLARE FITTINGS: SAE J513.

Quality Marks

REFRIGERATION PIPES: AENOR, TÜV, GL.

Instructions

Follow the equipment manufacturer’s installation instructions regarding refrigerant tubing, system evacuation and testing for leaks.

- Remove protective shipping plugs.

- Properly connect and tighten the flare nut to the approved level of torque.

- Take precautions not to crimp tube when bending.

- Take precautions not to tear the insulation.

- Do not allow contaminants to be introduced inside the network.

| Temper | EN 12735 Classification | Minimum Tensile strength Rm (MPa) | Min elongation, A% |

|---|---|---|---|

| Soft | R-220 | 220 | 40 |

| COPPER TUBE EXTERNAL DIAMETER INCH | COPPER TUBE EXTERNAL DIAMETER MM | COPPER TUBE WALL THICKNESS MM | OVERALL EXTERNAL DIAMETER WITH 9MM THICK INSULATION MM |

|---|---|---|---|

| 3/16 | 4,76 | 0,80 | 22,76 |

| 1/4 | 6,35 | 0,80 | 24,35 |

| 5/16 | 7,94 | 0,80 | 25,94 |

| 3/8 | 9,52 | 0,80 | 25,72 |

| 1/2 | 12,70 | 0,80 | 30,70 |

| 5/8 | 15,87 | 1,00 | 33,87 |

| 3/4 | 19,05 | 1,00 | 37,05 |

| 7/8 | 22,23 | 1,00 | 40,23 |

Values are listed, as obtained under standard laboratory conditions and may be amended, without prior notice.

| COPPER TUBE EXTERNAL DIAMETER INCH | COPPER TUBE EXTERNAL DIAMETER MM | COPPER TUBE WALL THICKNESS MM | OVERALL EXTERNAL DIAMETER WITH 9MM THICK INSULATION MM |

|---|---|---|---|

| ¼-3 / 8 | 6,35-9,52 | 0,80-0,80 | 24,4-27,5 |

| ¼-1 / 2 | 6,35-12,7 | 0,80-0,80 | 24,4-30,7 |

| ¼-5 / 8 | 6,35-15,88 | 0,80-1,00 | 24,4-33,9 |

| ¼-3 / 4 | 6,35-19,05 | 0,80-1,00 | 24,4-37,10 |

| 3 / 8-1 / 2 | 9,52-12,7 | 0,80-0,80 | 27,5-30,7 |

| 3 / 8-5 / 8 | 9,52-15,88 | 0,80-1,00 | 27,5-33,9 |

| 3 / 8-3 / 4 | 9,52-19,05 | 0,80-1,00 | 27,5-37,1 |

| ½-3 / 4 | 12,7-19,05 | 0,80-1,00 | 30,7-37,1 |

Other sizes and special packaging in pallets or cardboard boxes are available upon request.

Other sizes and special packaging in pallets or cardboard boxes are available upon request.

| MATERIAL | PE-X foam |

| DENSITY ACCORDING TO DIN 53420 ASTM D 1667 | 30-33 Kg/m3 |

| THERMAL CONDUCTIVITY COEFFICIENT (λ) ACCORDING TO ASTM C 335 | 0,039 W/m.K |

| VAPOUR-WATER DIFFUSSION RESISTANCE COEFFICIENT (μ) ACCORDING TO ISO 12572 | > 9.000 |

| WORKING TEMPERATURE | -80oC to +110oC |

| FIRE RESISTANCE | EN 13501–1, Class B or Class E, DIN 4102, B2, BS 476, NF P 92 501-M1 |

| RESISTANCE TO CHEMICAL AGENTS ACC. TO ASTM 543-56 T | Very good |

| SOUND ABSORPTION ACC. TO DIN 4109 300-2500Hz | ~60% |

| DIMENSIONAL STABILITY ACCORDING TO ISO 2796 FOR TEMPERATURES UP TO 1000C | <5% |

Values are listed, as obtained under standard laboratory conditions and may be amended, without prior notice.