CUSMART®

Our product range is designed with a commitment to excellence, delivering unmatched durability and efficiency to meet your needs. Engineered for reliability and performance, each product offers exceptional value, ensuring long-lasting solutions that enhance your experience. Whether you’re seeking practicality or innovation, our range provides reliable results you can count on every time.

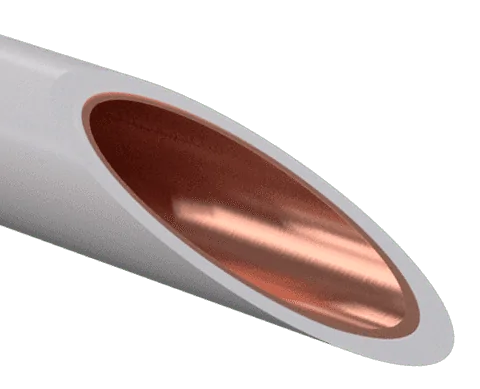

CUSMART® flexible copper tubes are unsurpassed in every technical aspect, offering great installation ease. Their exceptional flexibility allows cold bending and even manual shaping without “memory” effects. The use of CUSMART®flexible copper tubes in plumbing, cuts down on installation time and cost, offering uncompromised security.

CUSMART® flexible copper tubes are patented flexible copper tubes with a special compound coating. They preserve their physical and technical properties throughout their lifetime and are covered by a 20-year manufacturer’s guarantee.

CUSMART® superiority in every aspect

- Long lifetime

- A special process that ensures hygiene

- High pressure and temperature fluctuation resistance

- Unique flexibility and final shape stability

- Exceptional thermal conductivity

- Minimum thermal expansion

- Cost-effective system

- Impermeability – 100% Oxygen Barrier

- Recyclable product

- UV resistance and maximum corrosion resistance

- Significant energy savings with industrial insulation

Product Description

CUSMART® flexible copper tubes are coated with a special white colored compound for enhanced endurance at temperatures up to 95 oC.

Quality Marks

RAL, NSF*.

* Only products bearing the NSF Mark on the product, product packaging, and/or documentation shipped with the product are certified.

| Temper | Minimum Tensile strength Rm (MPa) | Min elongation, A% |

|---|---|---|

| Soft | 220 | 40 |

STRAIGHT HALF HARD

| NOMINAL DIMENSIONS (MM) | OUTSIDE DIAMETER – (OD)(MM) | WALL THICKNESS (MM) | INSIDE DIAMETER (ID)(MM) | INSIDE DIAMETER CROSS-SECTION (CM2) | WATER VOLUME (L/M) | MAXIMUM WORKING TEMPERATURE (OC) | THERMAL CONDUCTIVITY COEFFIENT W/(M*OK) | MINIMUM BENDING RADIUS WITH BENDING TOOL (MM) | MINIMUM BENDING RADIUS WITH EXTERNAL BENDING SPRING=4X OD(MM) | BENDING RADIUS MANUAL =6X OD(MM) | PACKAGING STRAIGHT LENGTHS | PACKAGING COILS (M) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 14Χ2 | 14 | 2 | 10 | 0,785 | 0,0785 | 95 | 0,4 | 39 | 56 | 84 | 3 | 100/ 50 |

| 16Χ2 | 16 | 2 | 12 | 1,131 | 0,1131 | 95 | 0,4 | 45 | 64 | 96 | 3 | 100/ 50 |

| 18Χ2 | 18 | 2 | 14 | 1,5 | 0,154 | 95 | 0,4 | 53 | 72 | 108 | 3 | 100/ 50 |

| 20Χ2 | 20 | 2 | 16 | 2,011 | 0,2011 | 95 | 0,4 | 64 | 80 | 120 | 3 | 100/ 50 |

| 26Χ3 | 26 | 3 | 20 | 3,142 | 0,3142 | 95 | 0,4 | 89 | 104 | 156 | 3 | 25/ 50 |

| 32Χ3 | 32 | 3 | 26 | 5,309 | 0,5309 | 95 | 0,4 | 128 | 128 | 192 | 3 | 25 |

Different dimensions and lengths are available upon request.

| NOMINAL DIMENSION (MM) | TOTAL OUTSIDE DIAMETER (INSULATION THICKNESS: 9 MM) | PACKAGING – COIL (M) |

|---|---|---|

| 14X2 | 32 | 100/ 50 |

| 16X2 | 34 | 100/ 50 |

| 18X2 | 36 | 100/ 50 |

| 20X2 | 38 | 100/ 50 |

| 26X3 | 44 | 25/ 50 |

| 32X3 | 50 | 25 |

CUSMART® flexible tubes with external industrial insulation are suitable for all heating and hot water supply plumbing networks inside and outside buildings. The insulation is a cross-linked polyethylene (PE-X) foam structured in closed type microcells. Energy saving is a result of the spectacular reduction of temperature loss to over 50% compared to similar networks without insulation.

The CUSMART® all-inclusive flexible copper tube system includes a full range of CUSMART FITTINGS (press and compression fittings), as well as tools, ensuring reliable results in every application.

| MATERIAL | PE-X or PE foam |

| DENSITY ACCORDING TO DIN 53420 ASTM D 1667 | 30-33 Kg/m3 |

| THERMAL CONDUCTIVITY COEFFICIENT (λ) ACCORDING TO EN ISO 8497 | 0.0357 W/mK (0oC)0,0389 W/mK (40oC) |

| VAPOUR-WATER DIFFUSSION RESISTANCE COEFFICIENT (μ) ACCORDING TO EN 13469 | 12.500 |

| WORKING TEMPERATURE | -80oC to +110oC(+90oC for PE foam) |

| FIRE RESISTANCE | EN 13501–1, Class B or Class E, DIN 4102, B2, BS 476, NF P 92 501-M1 |

| RESISTANCE TO CHEMICAL AGENTS ACC. TO ASTM 543-56 T | Very good |

| DIMENSIONAL STABILITY ACCORDING TO ISO 2796 FOR TEMPERATURES UP TO 1000C | <5% |

Values are listed, as obtained under standard laboratory conditions and may be amended, without prior notice.