Revolutionizing Valve Guides of Automotive Industry with High Tensile Brass CW713R

One of our notable achievements involves the development of High Tensile Brass CW713R. A client approached us with precise specifications for valve guides, in automotive engine, requiring an intricate balance of microstructure and mechanical properties.

Through targeted annealing treatments and the precise calibration of chemical element ratios, we achieved:

- the desired α-phase distribution,

- tensile strength,

- yield strength,

- elongation, and

- hardness properties.

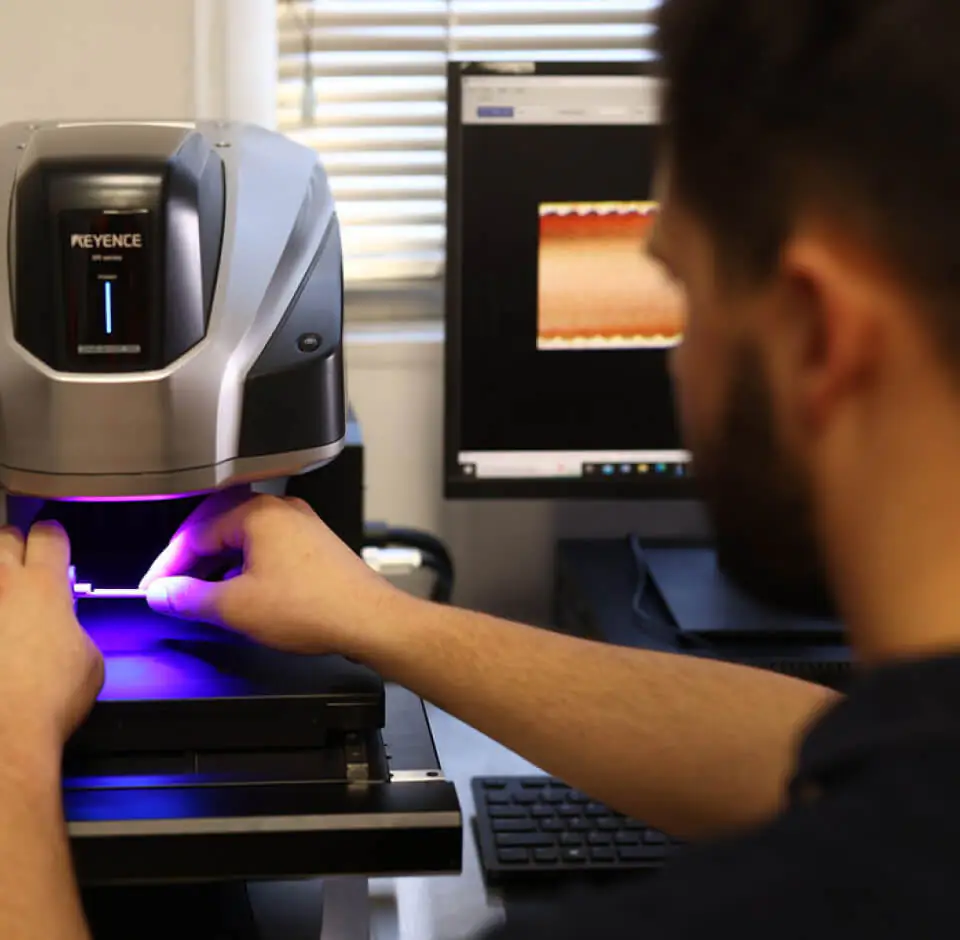

For this investigation, expertise knowledge was exchange with Hellenic Research Centre for Metals (ELKEME). Software programs were used in order to simulate phase diagrams and define the effect of every chemical element content to microstructure alterations as the temperature decrease. In order to verify the results, trials were conducted with the use of laboratory annealing furnaces depending to heat treatment temperature.

This project exemplifies our dedication to fulfilling and exceeding the special requirements of our clients, marking a significant milestone in custom metallurgical solutions.